Summary

Sector: Robotics, Assistive Technology

Software: SolidWorks

Manufacturing: 3D Printing

Project Time: 8 weeks

Inspired by MIT's Rovable robot, I worked on developing a wearable robotic assistant capable of climbing clothing and communicating with the user. The major challenges of this project were:

1. Creating a wearable robot capable of traversing clothing

2. Relay important information via the robot by movement, vision or touch

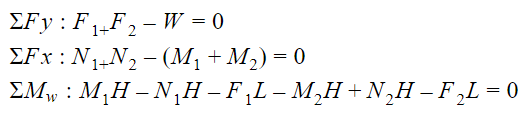

Physics Model

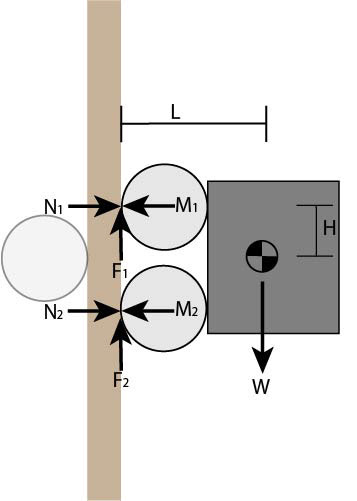

In order to better understand how Rovable's robot worked I started with the basic statics equations and a free body diagram (below). The tan rectangle is the fabric, N is the normal force, M is the magnet attraction, F is the friction force, W is the mass acting at the center of mass, L and H mark distance to the center of mass.

From the MIT Rovables paper we know the magnetic attraction (M1+M2) of their magnets to be a maximum of 4.2N when there is no fabric present. The intensity of a magnetic field falls off with 1/d2 where d is the distance. By using the fabric thickness as d and knowing the coefficient of friction it’s possible to calculate if the robot will fall given a certain fabric.

Design Process

This has been a solo project with occasional advice from other members of the BEEM lab. My design uses the general concept of MIT's Rovable but designed with much cheaper electronics, custom fittings and Bluetooth communication instead of radio. I divided the project in to subsystems, making it easier to design and source needed parts. Tinycircuits.com was an excellent source for compatible small electronics.

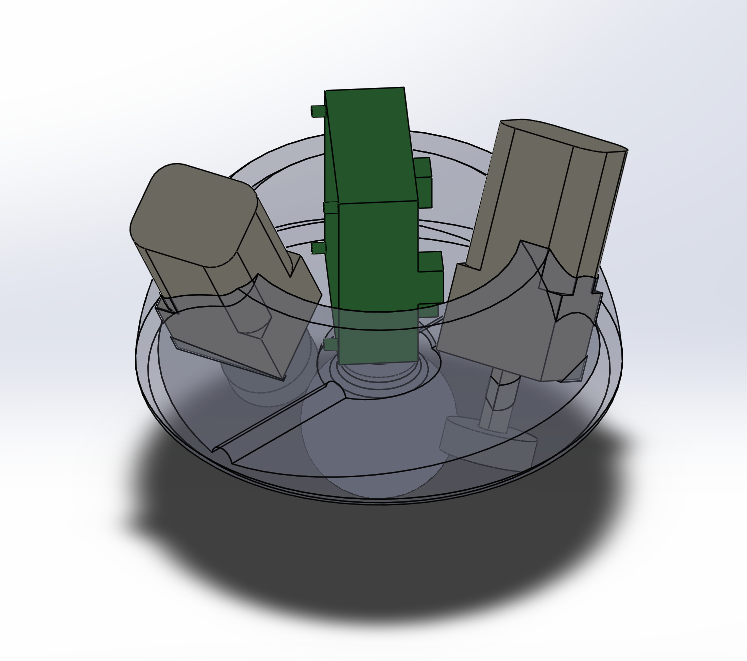

Next Iteration

The multi-wheel system above poses a number of problems. A wheel based system is bulky and uncomfortable to the user. It is also prone to jamming and getting caught on seams.

To achieve a lower profile and higher mobility a magnetic ball could be used to replace the wheels and underside axle in the current design. A magnetic ball would be placed under the clothing with two driven magnetic rollers above. These rollers would be placed on opposite sides of the ball allowing for movement in any direction including spinning on the spot. Challenges with this design include placing the motors in such an orientation that they will spin the ball effectively. In addition, sizing the ball correctly to be comfortable yet allow the ball to to traverse seams and not jam.

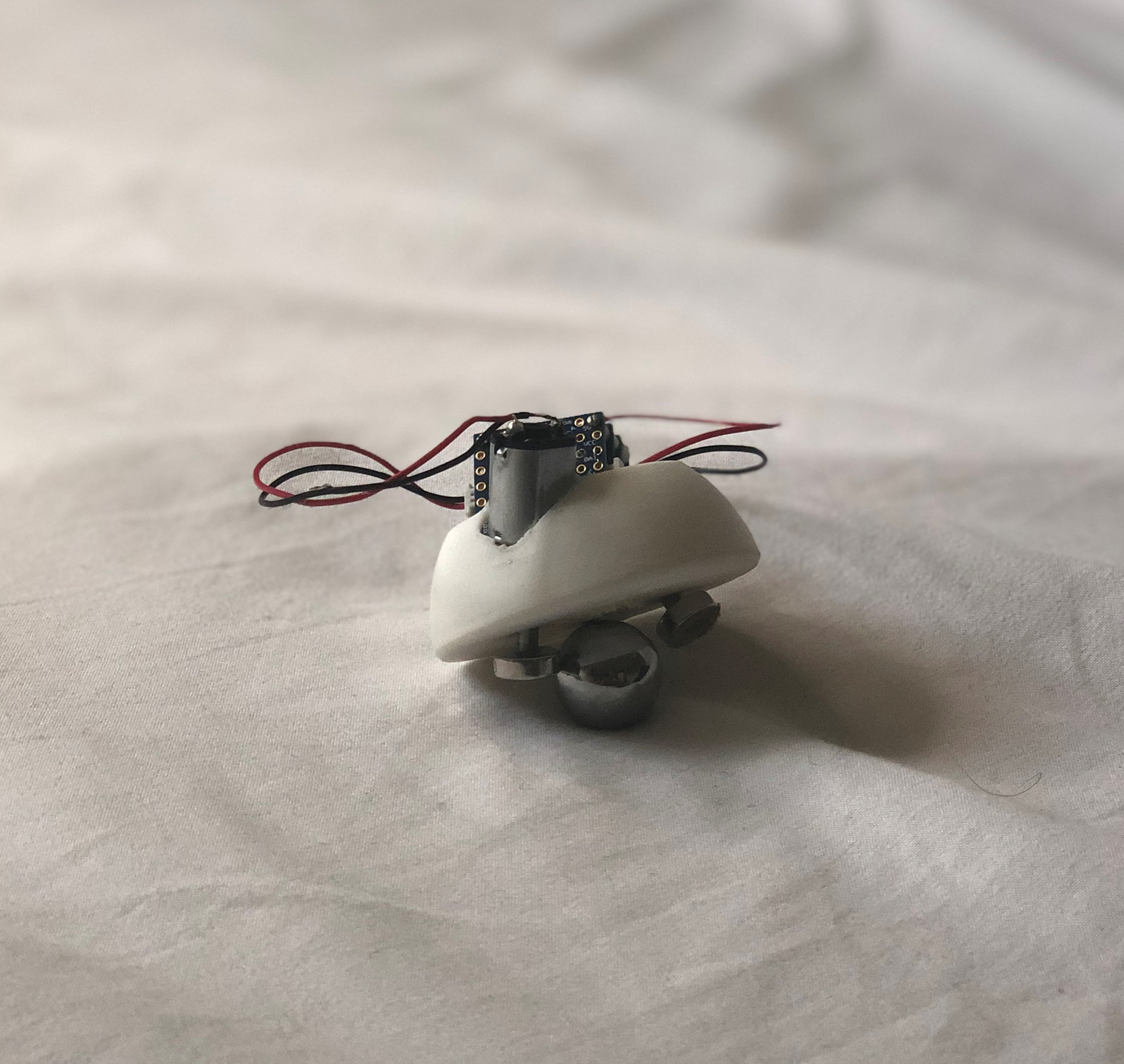

Next Iteration: Prototypes

The first draft of the magnetic ball design is shown. This prototype had problems with fabric bunching, contact with the motors and slipping.

To improve traction, the wheel angle was changed to increase surface area and the ball was coated with a spray rubber. Unfortunately, bunching would still slow and eventually stop the robot. Although this project did not achieve its goal of becoming an assistive robotic device it did teach me about system design and integration, robotics and iterative design.