Summary

The project for MCEN4026 (Manufacturing Process & Systems) was to take a household appliance, analyze it in detail and design an assembly line. It was a fun project and it taught me about assembly, standardization, and injection molding. A group member had an old automatic can opener so we used it as our designated household appliance. I was a CAD designer along with a team of 3 others.

Design Process

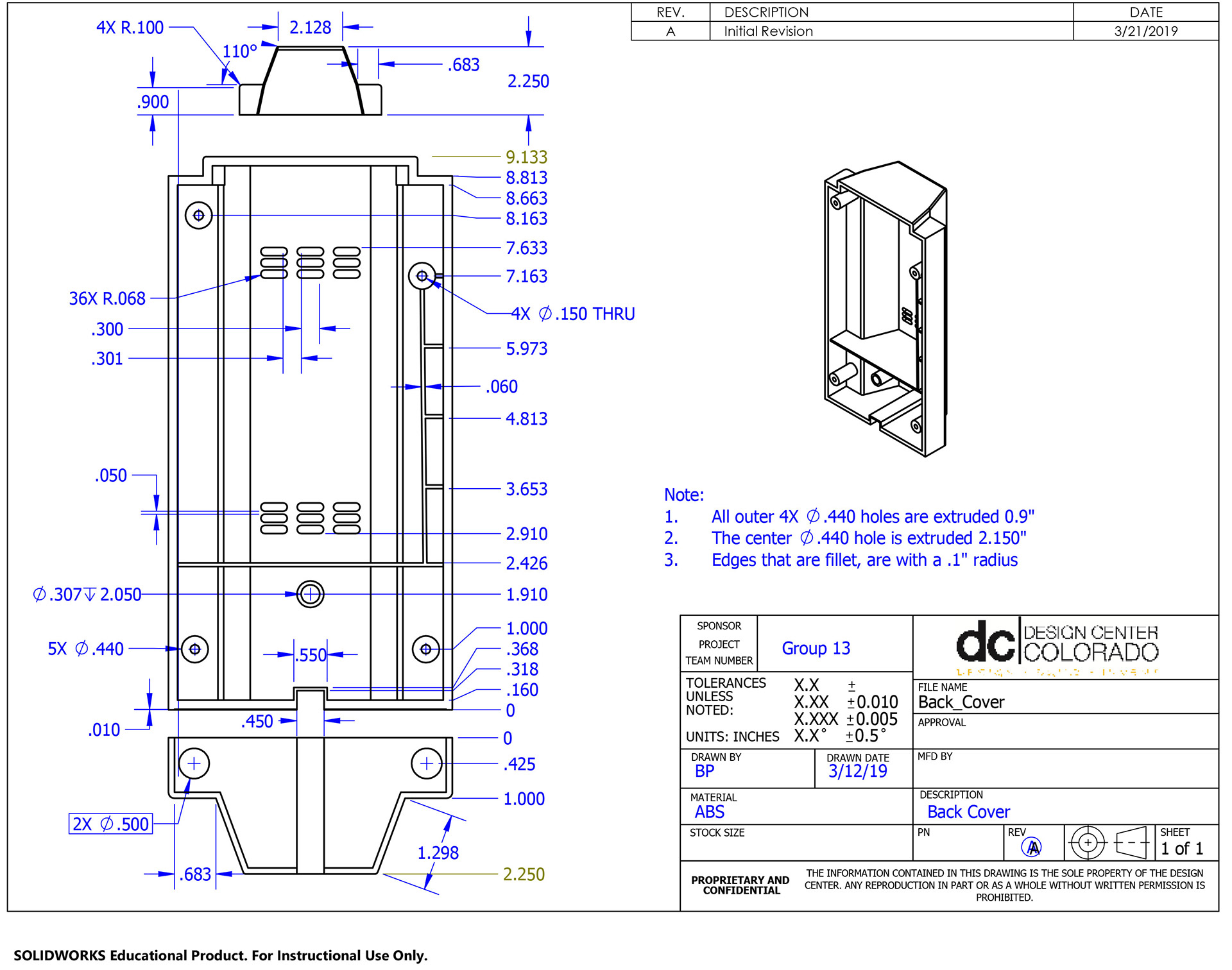

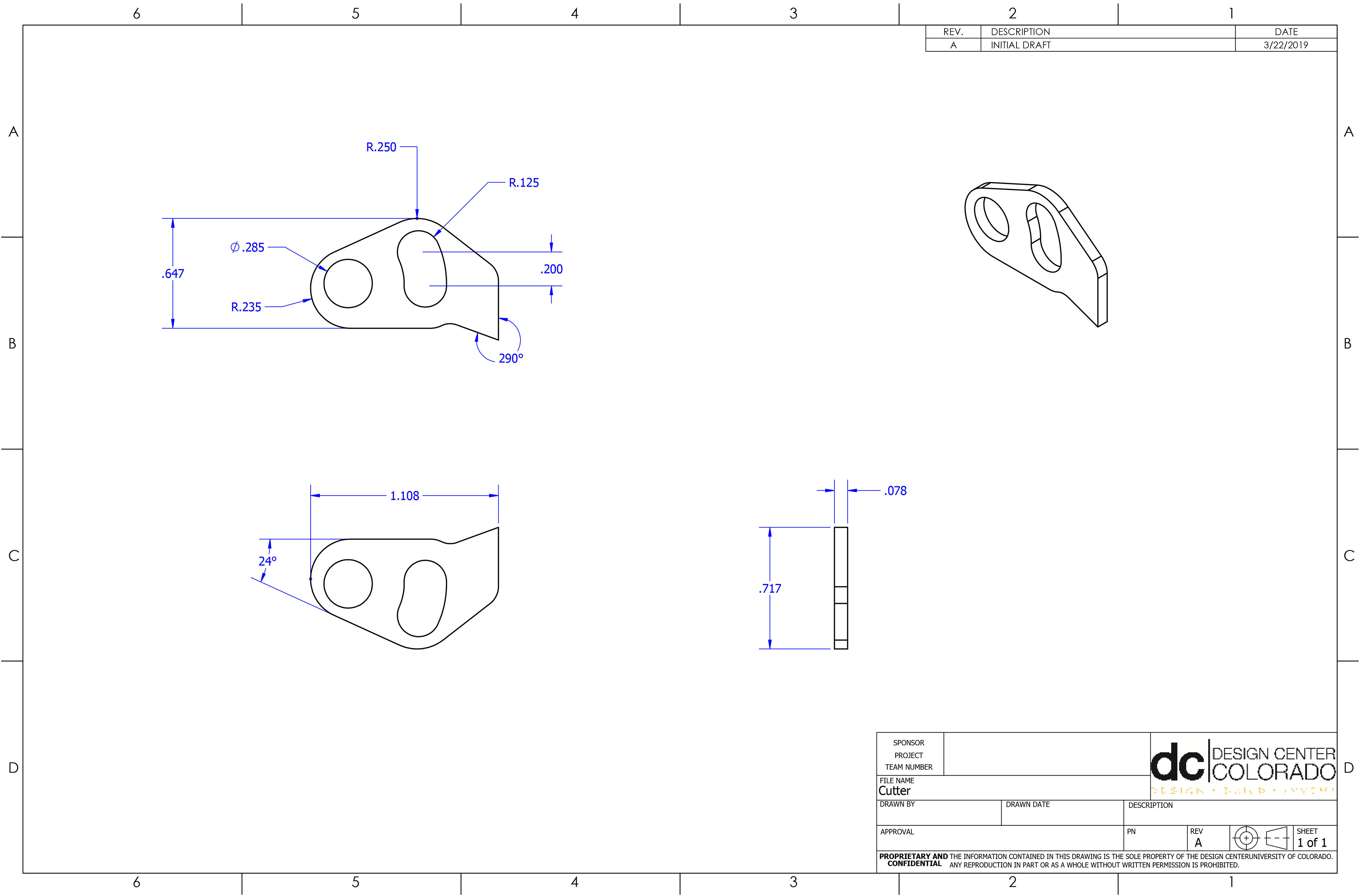

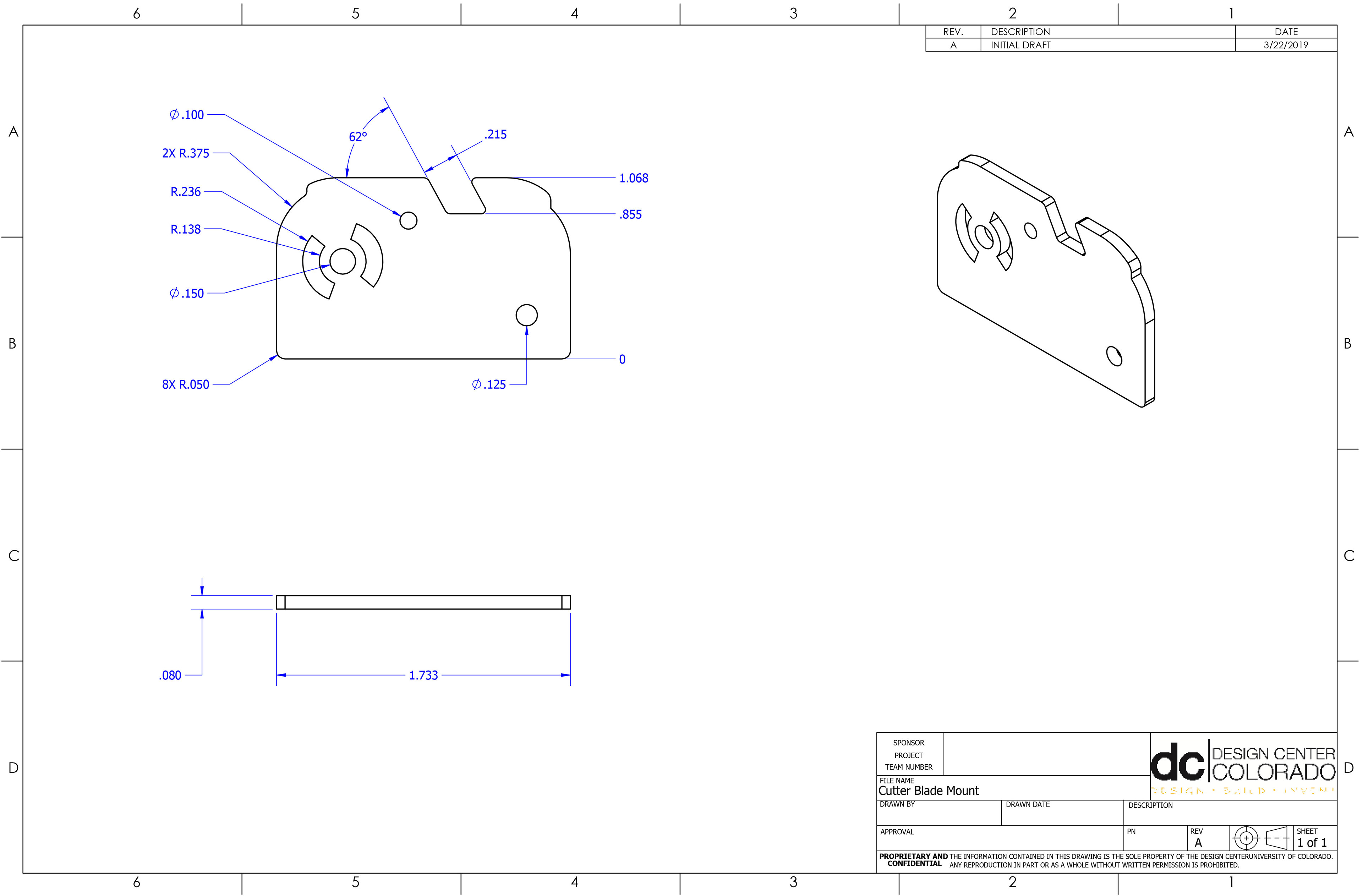

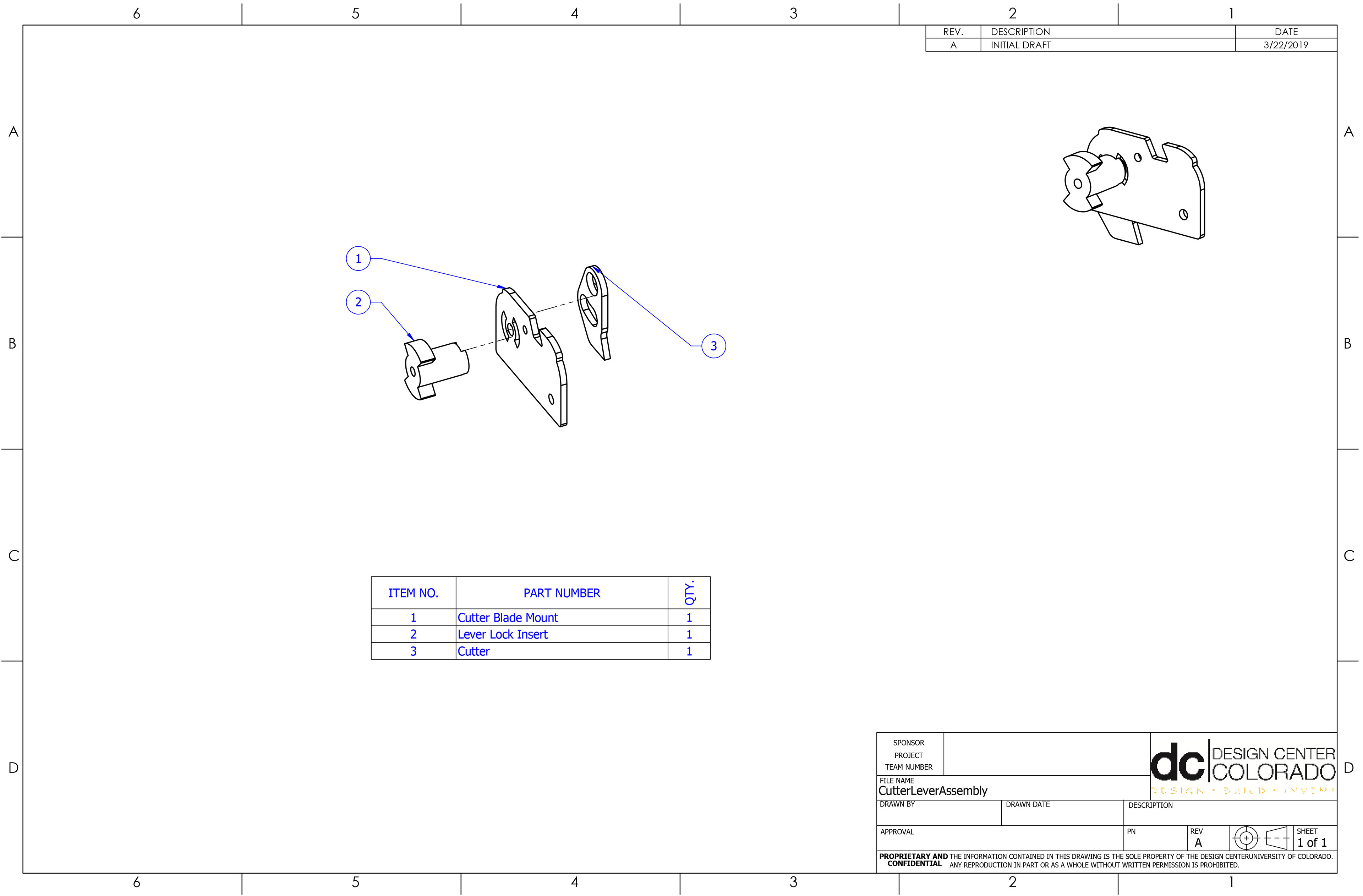

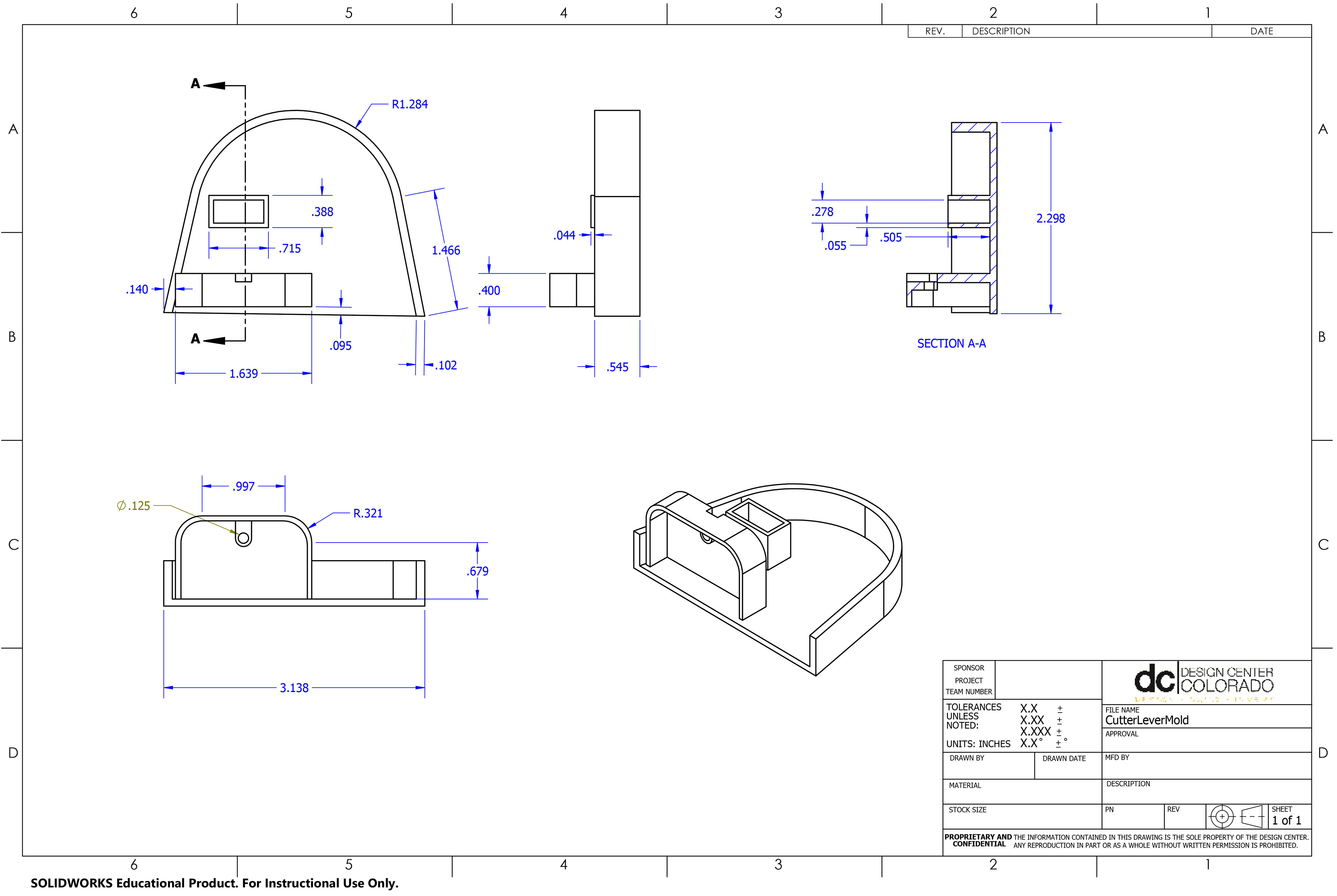

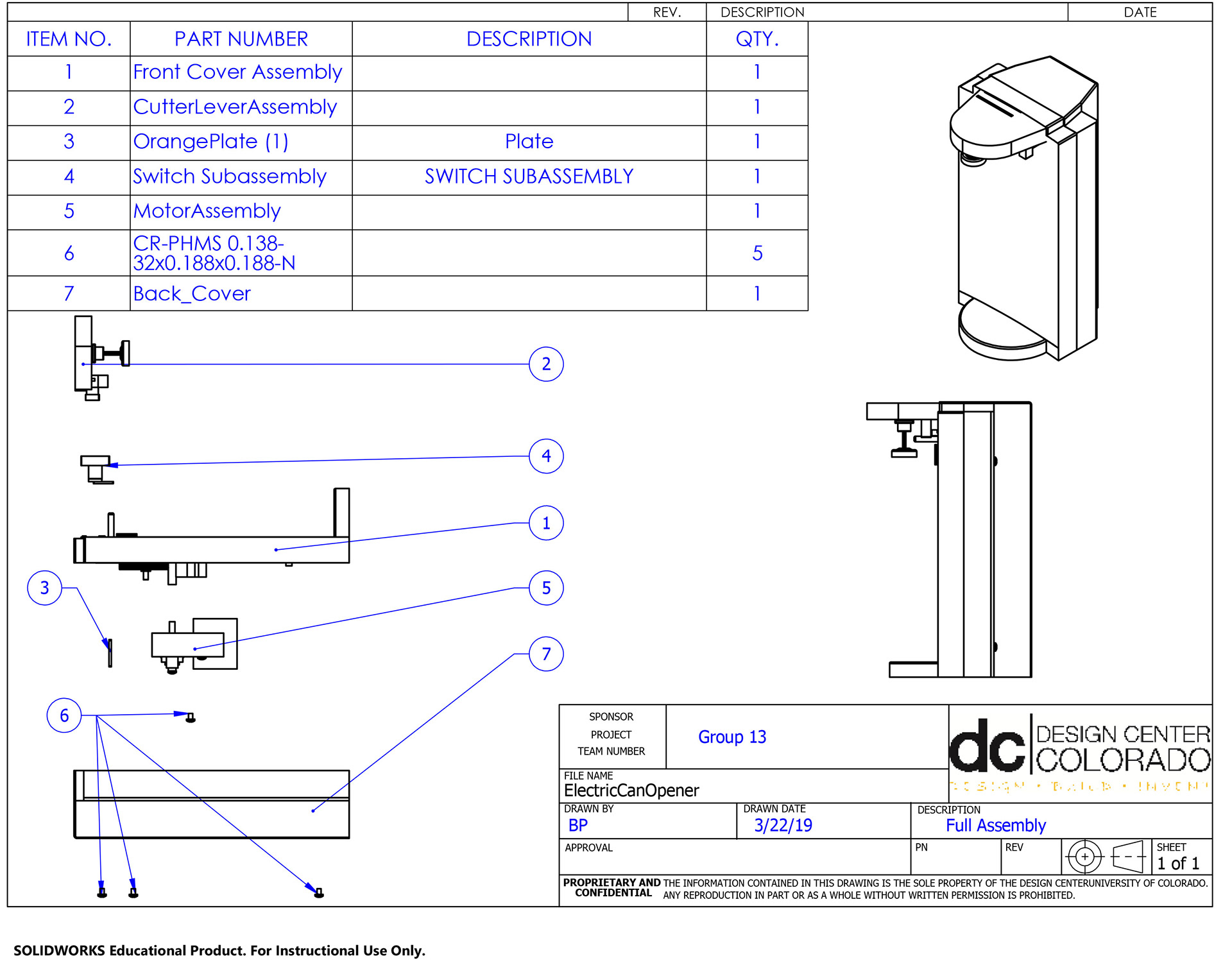

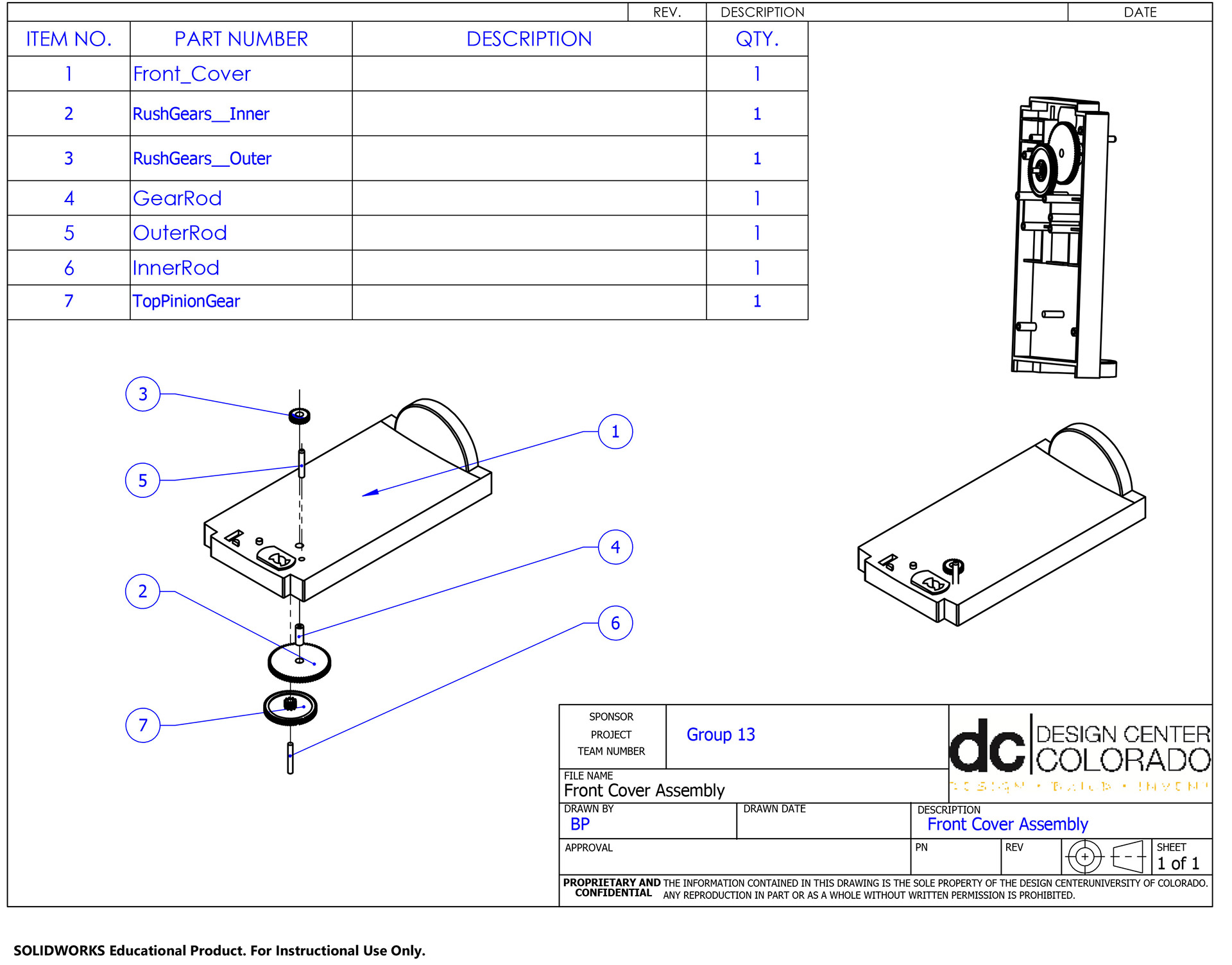

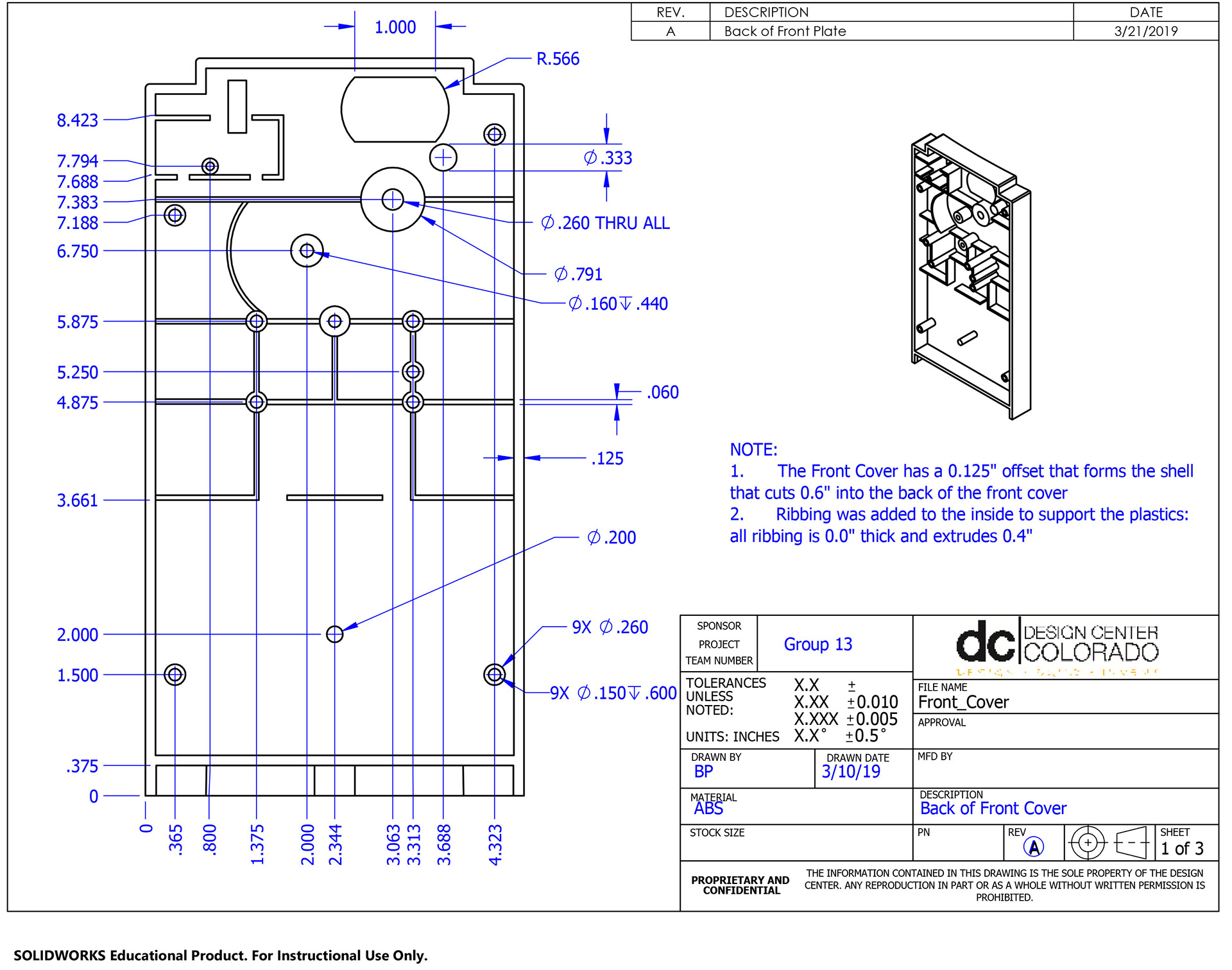

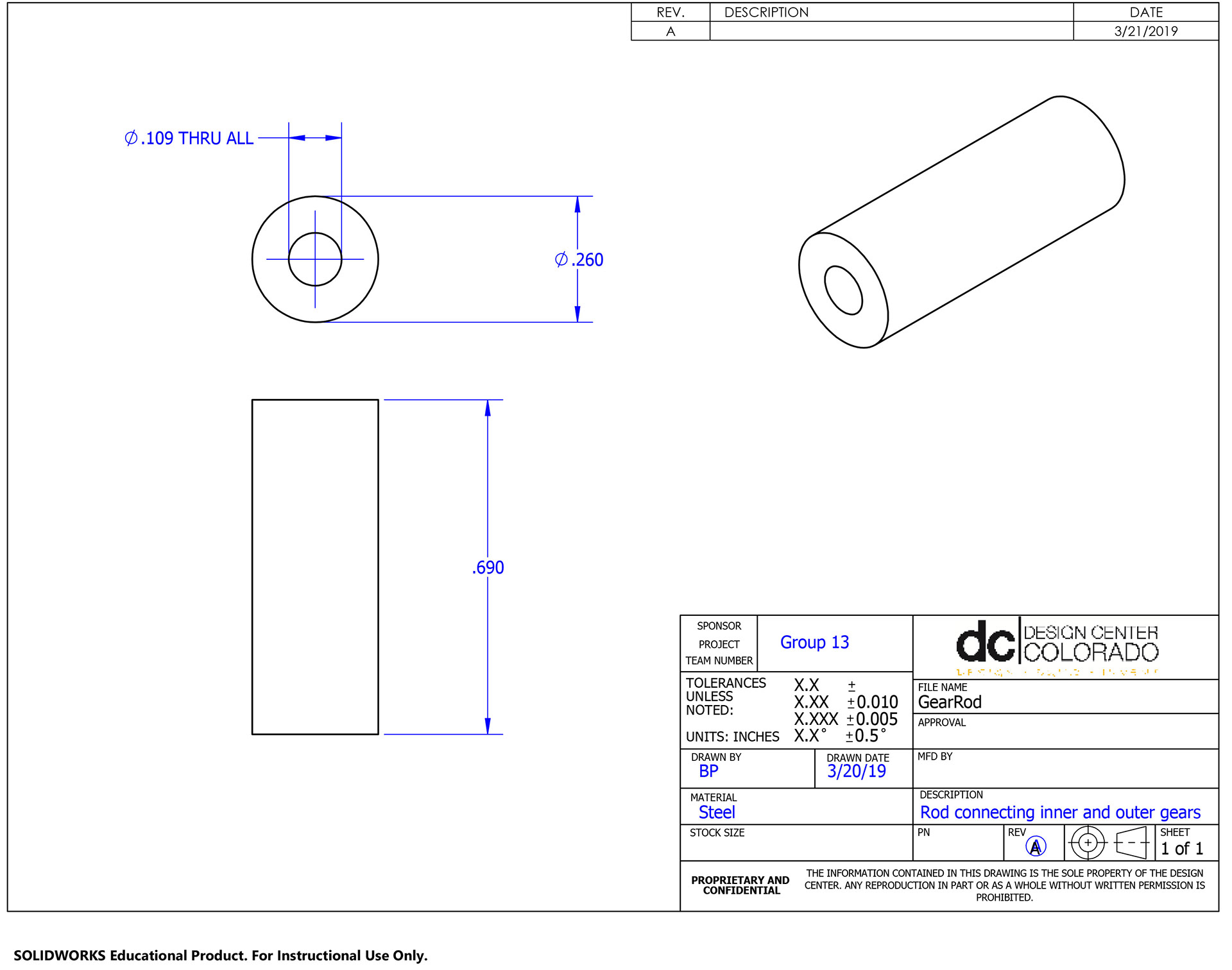

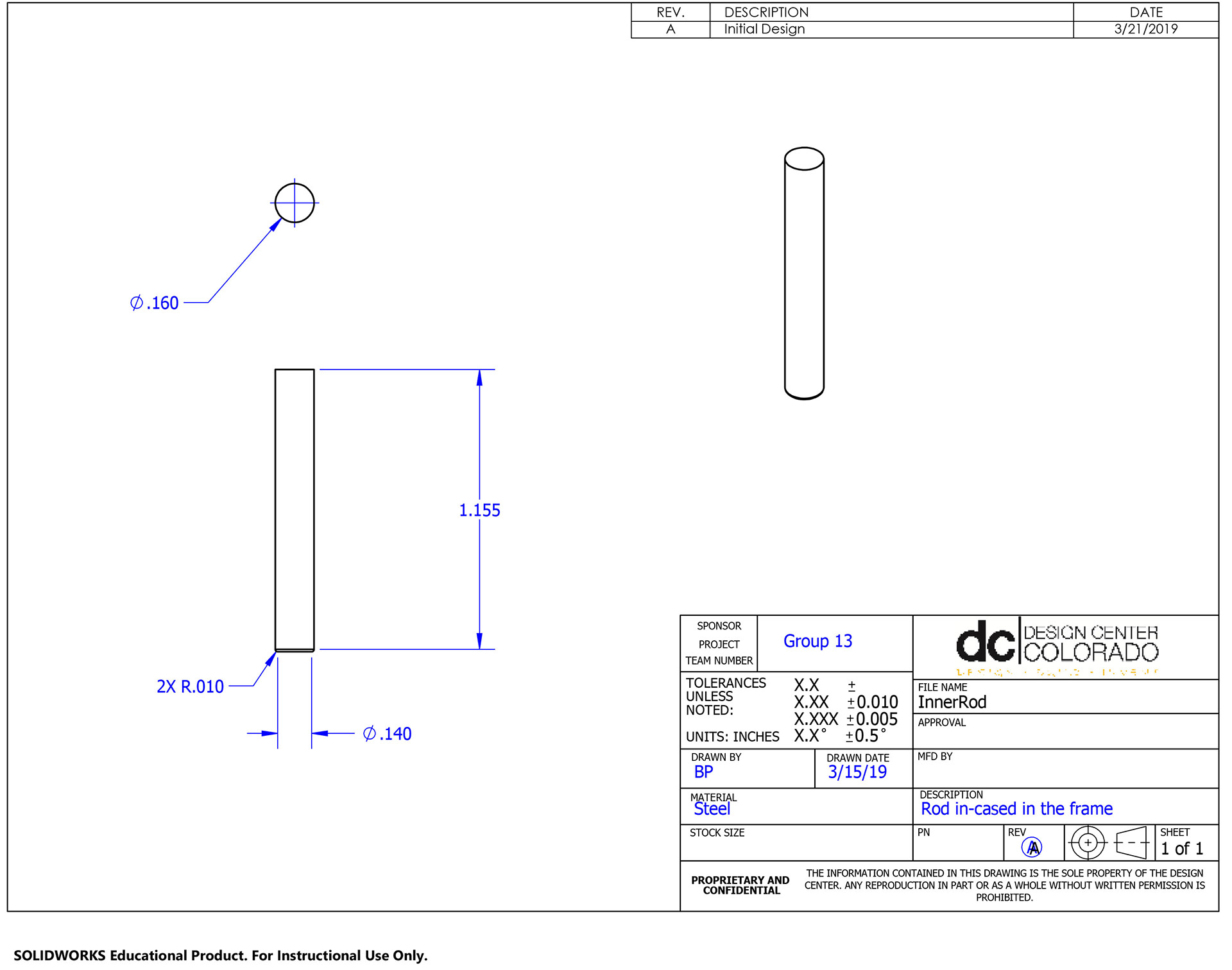

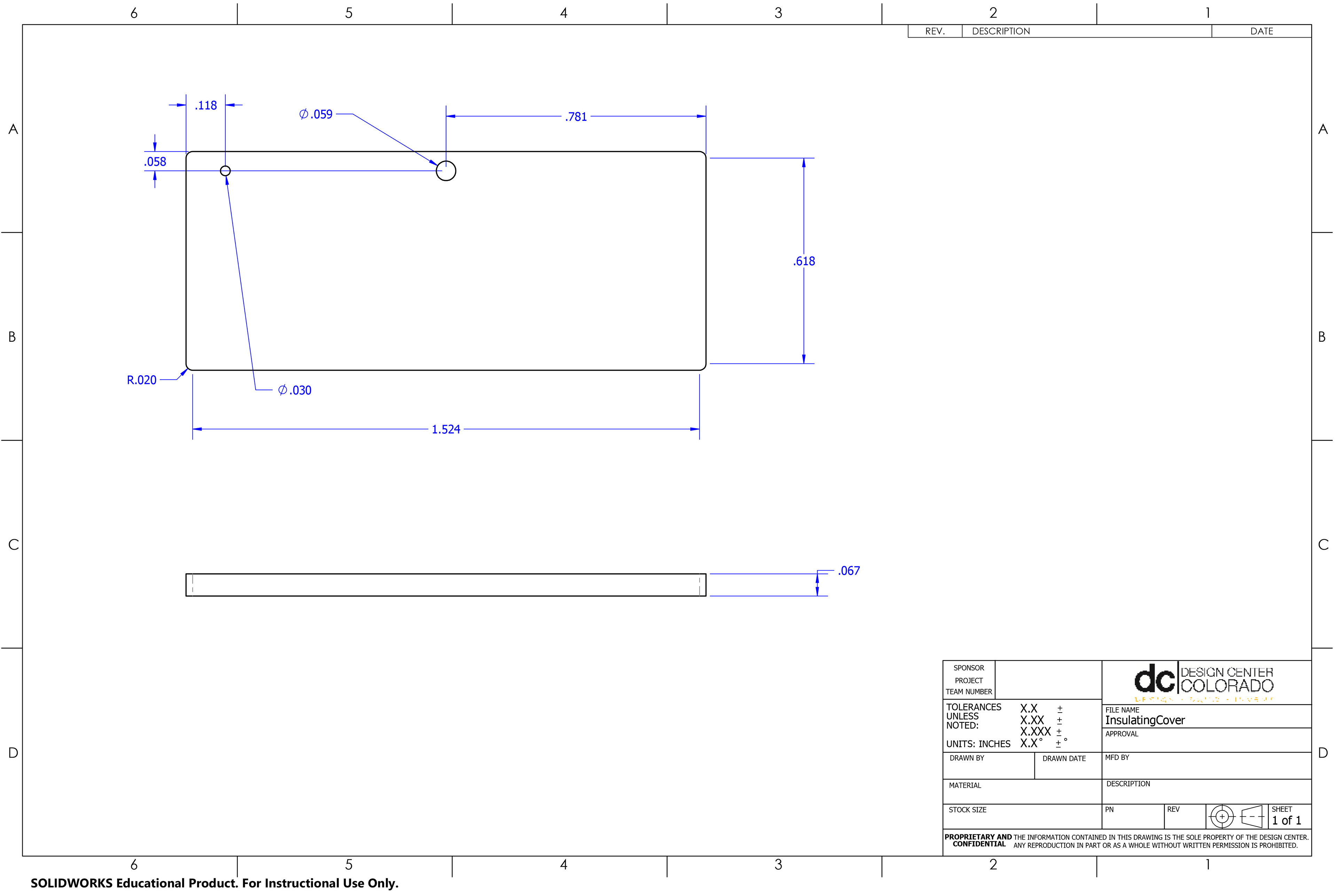

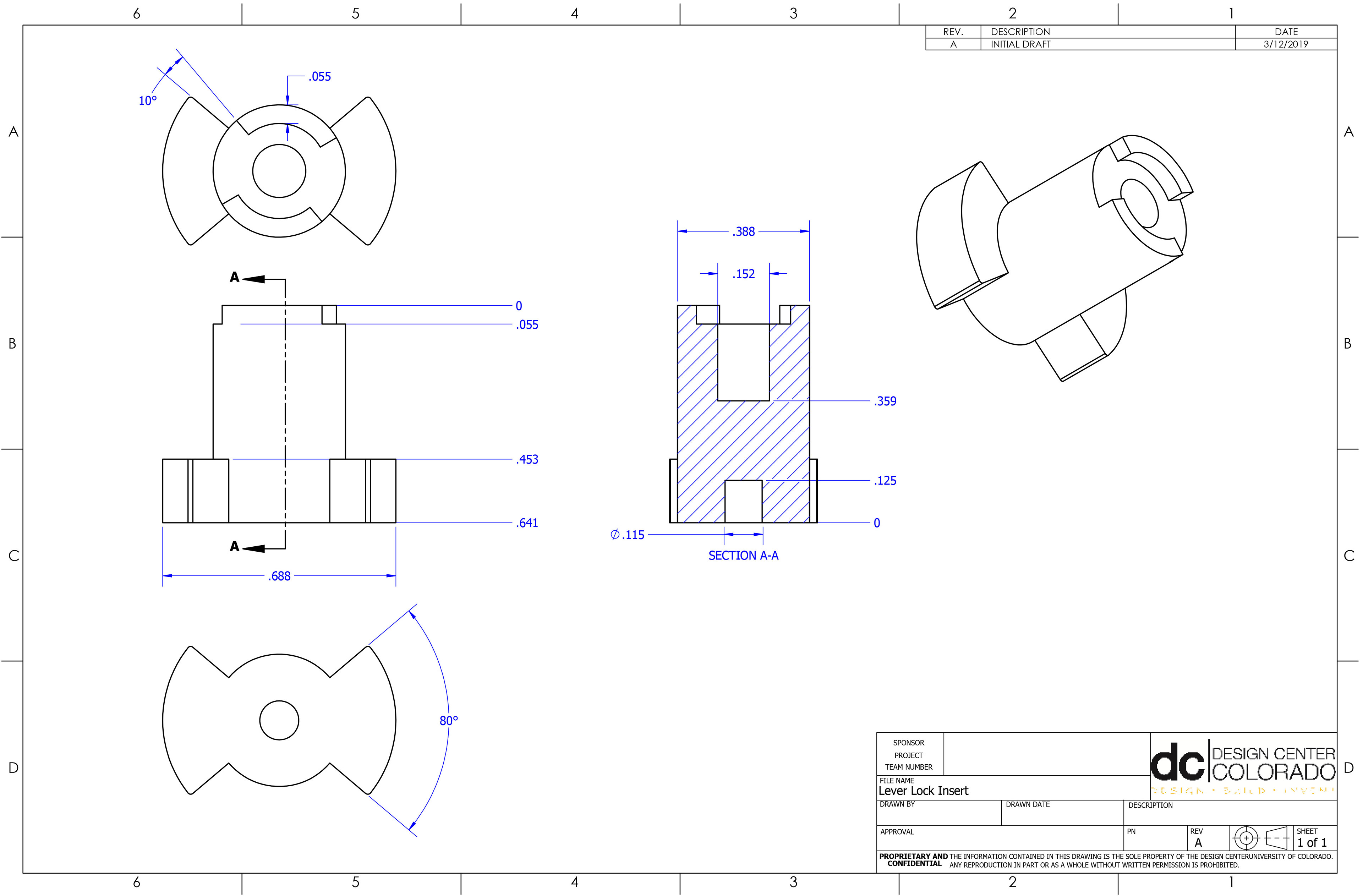

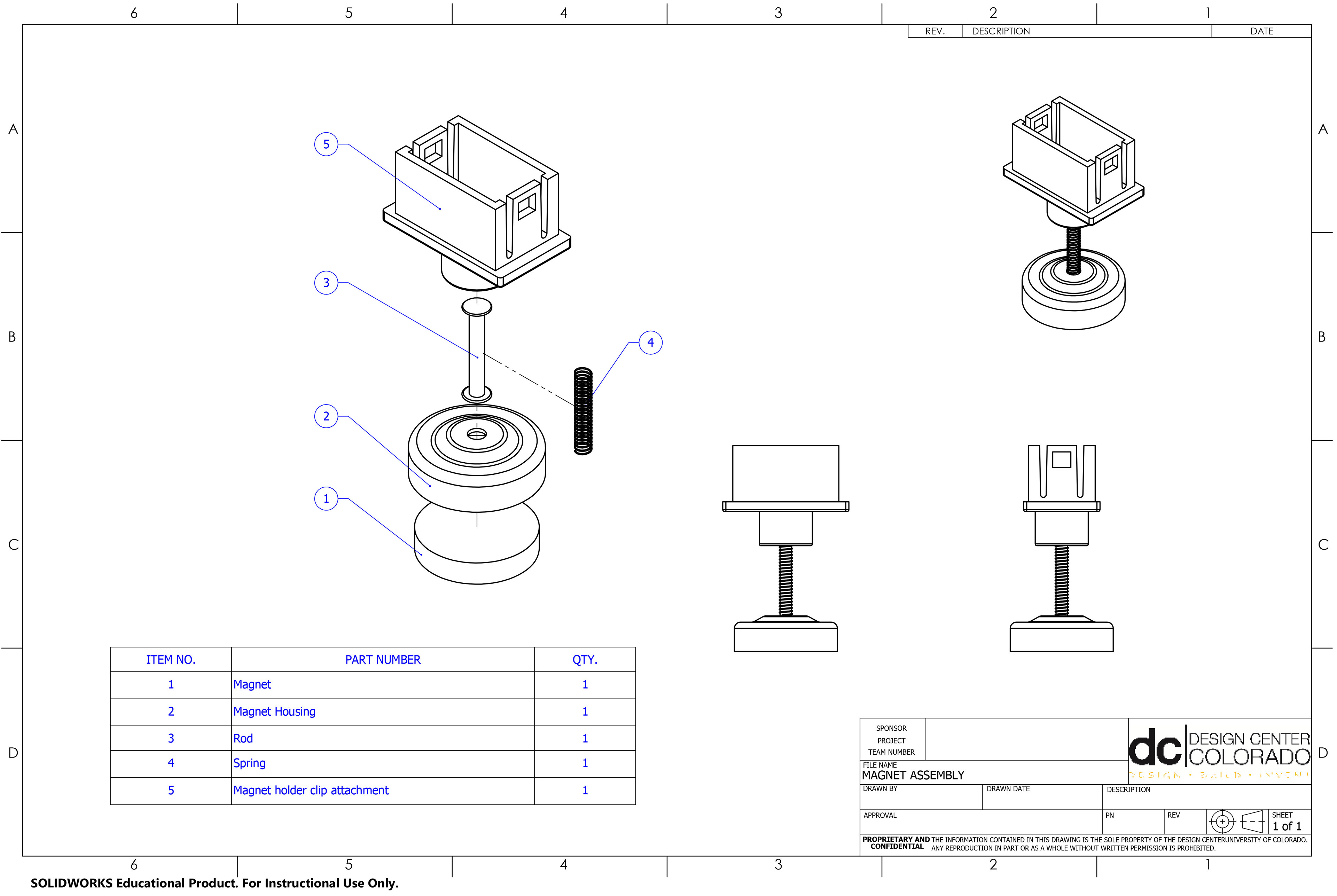

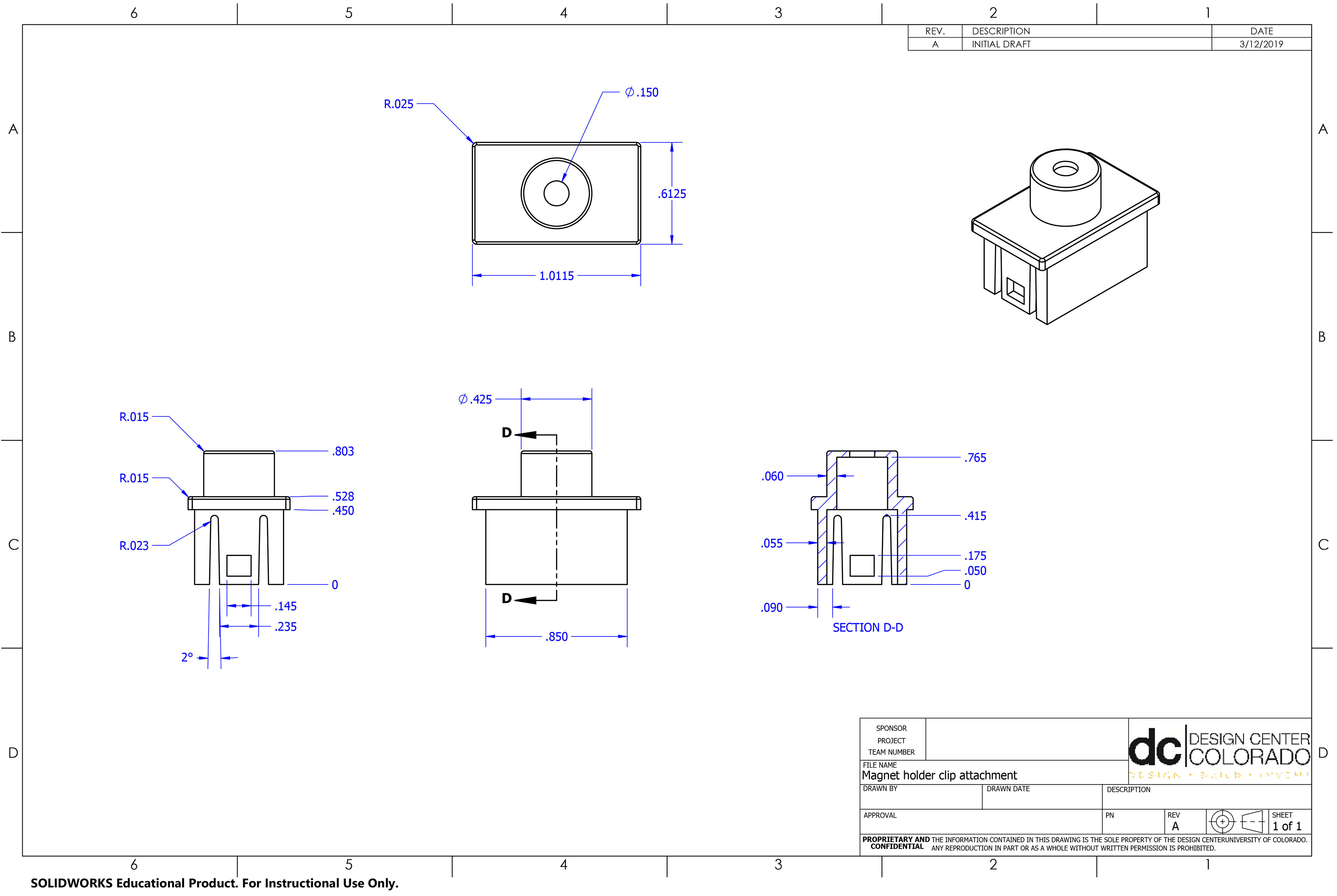

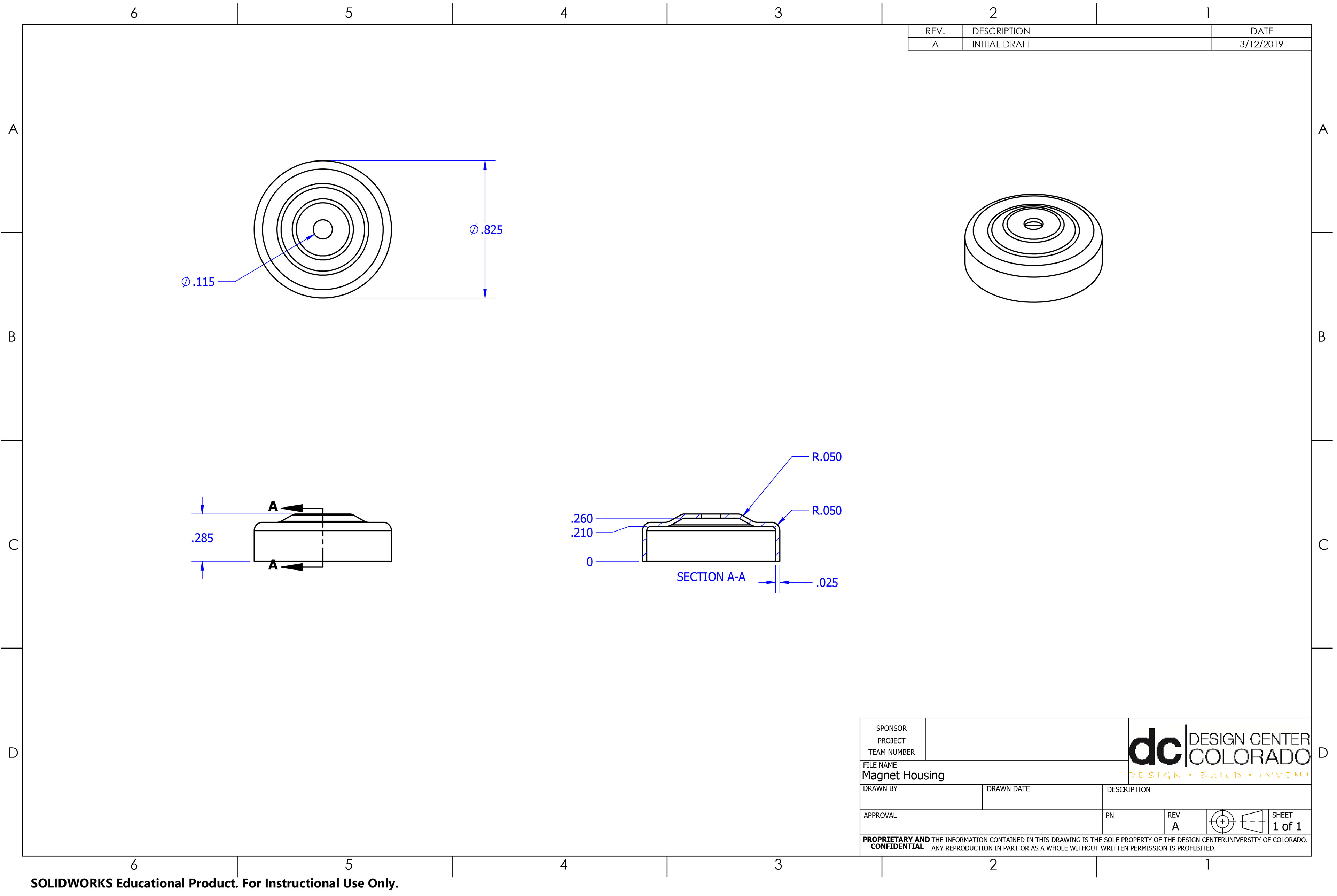

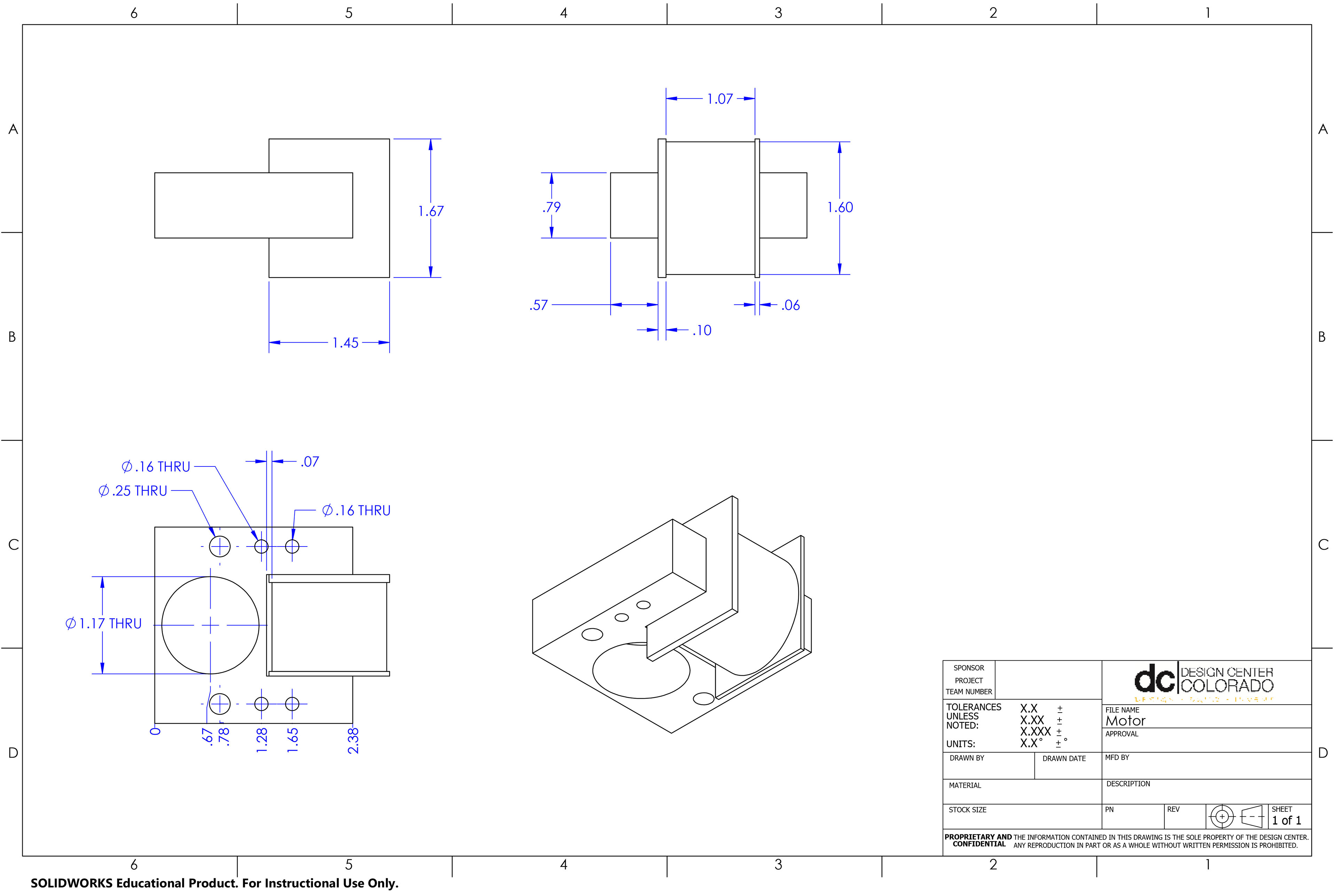

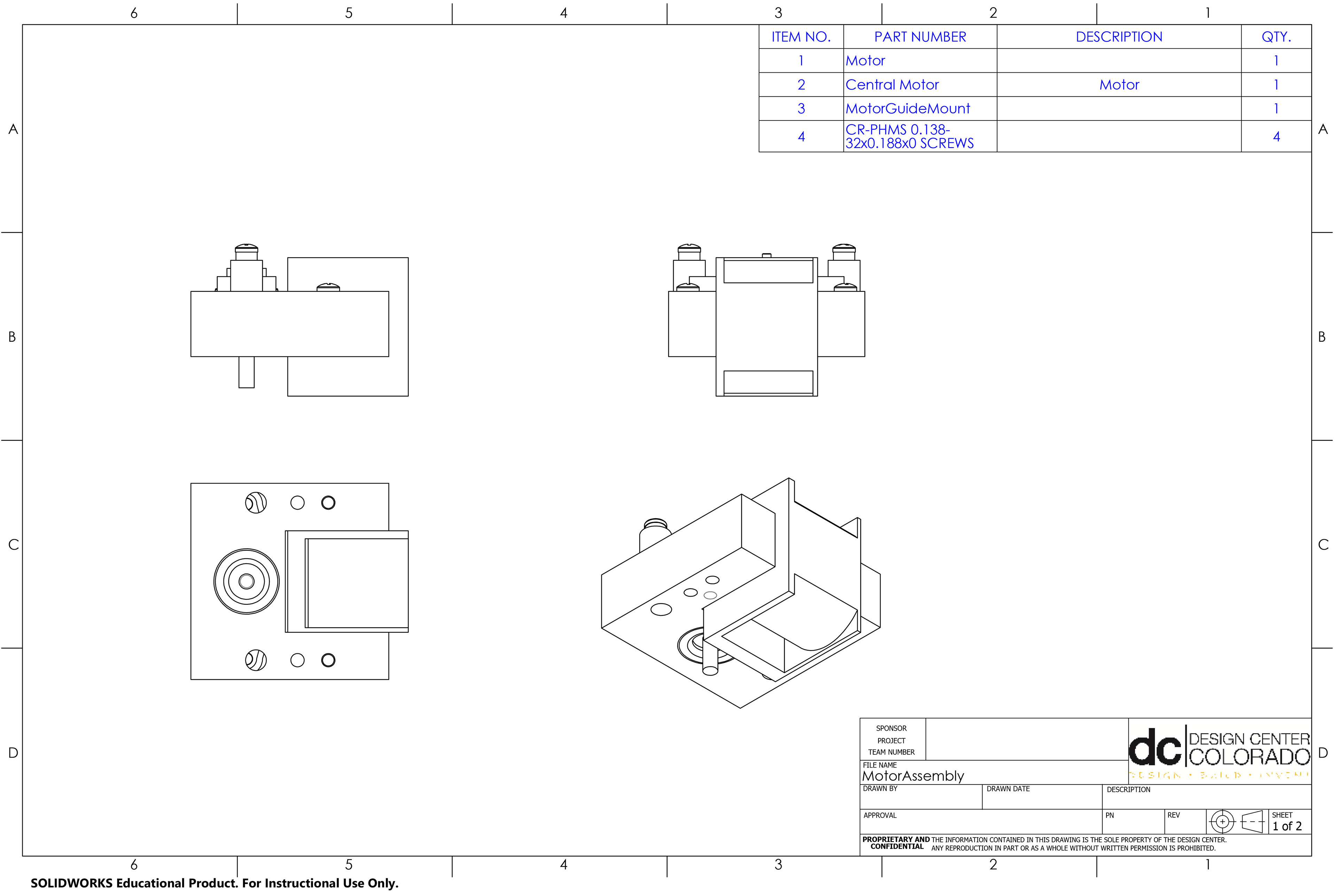

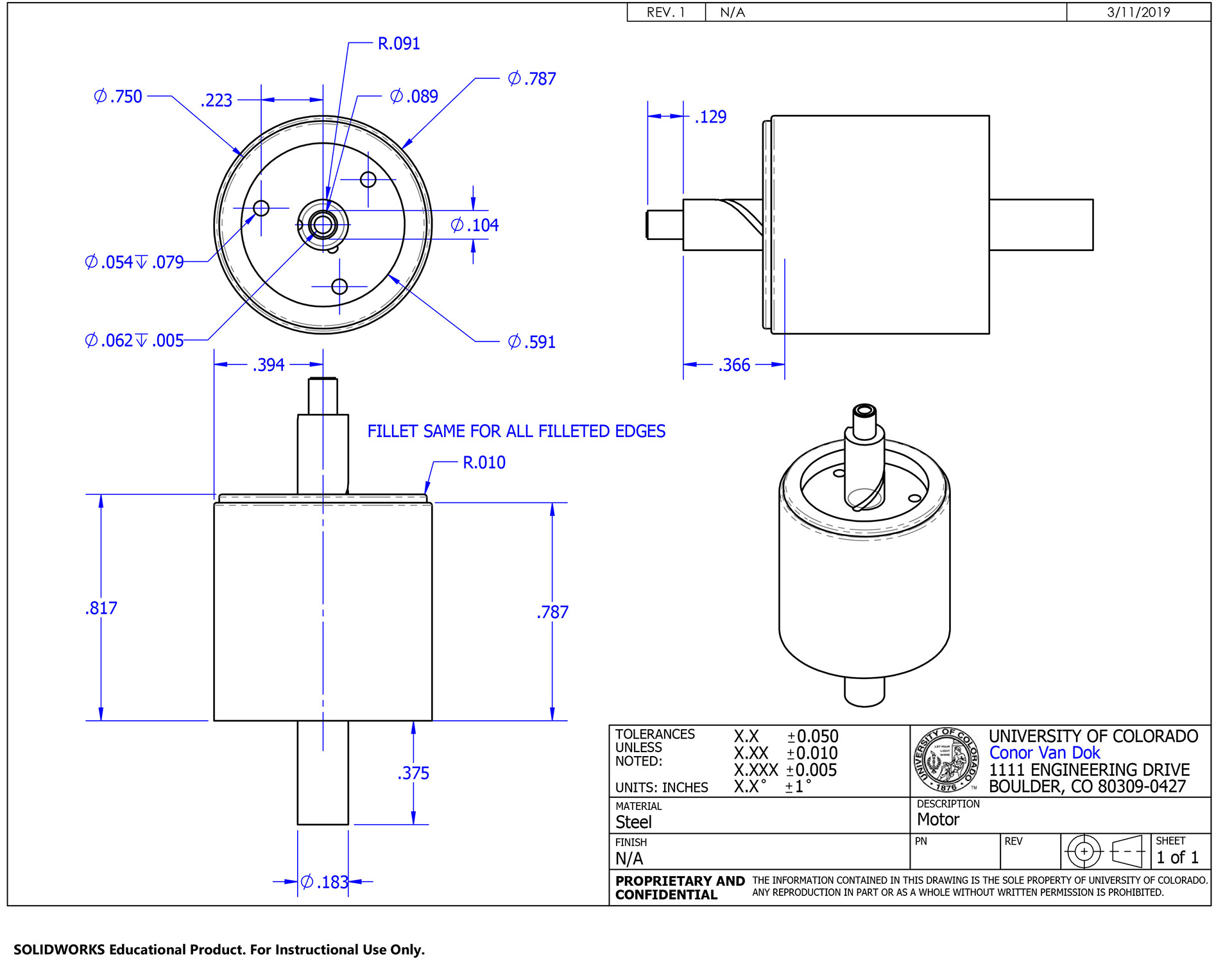

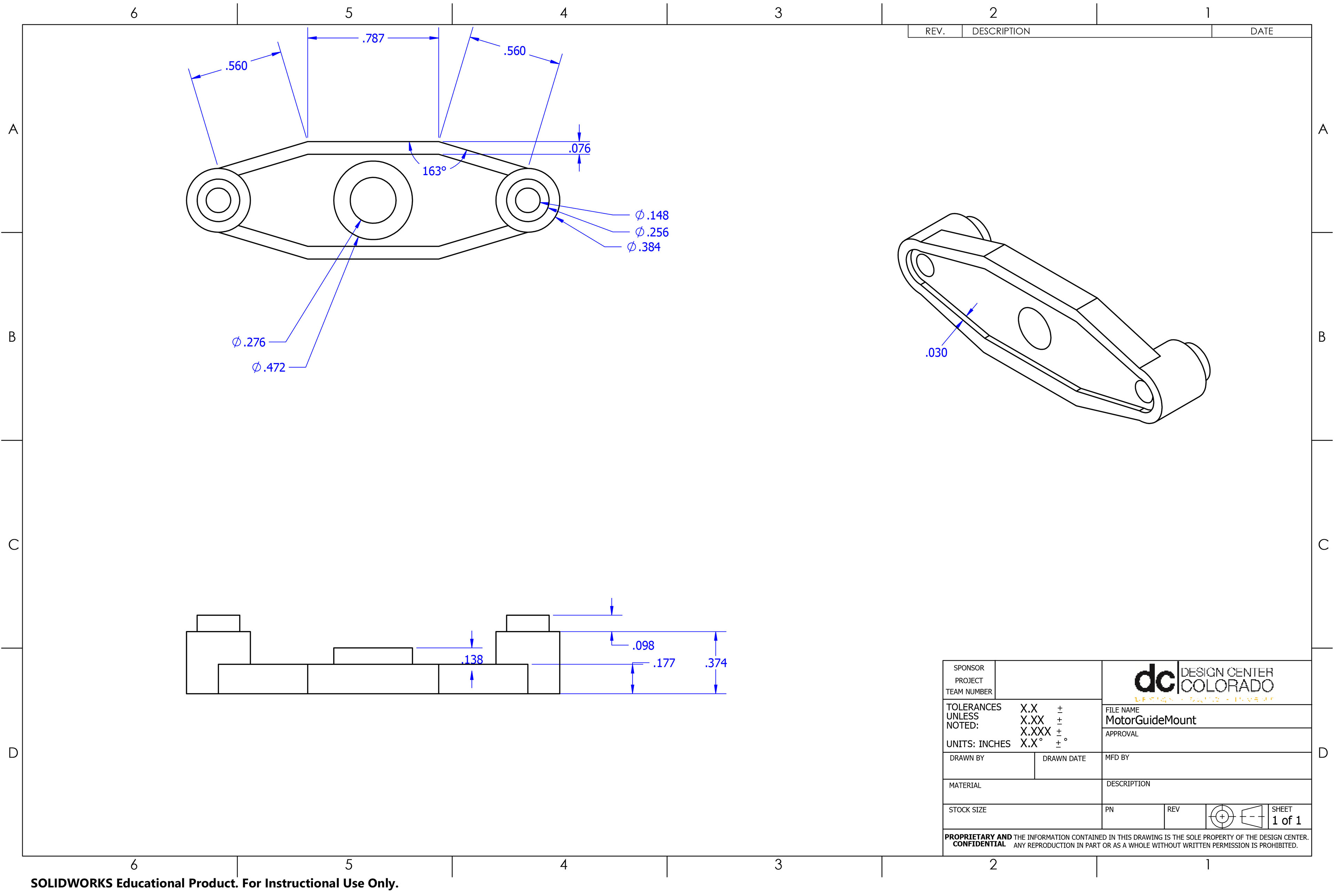

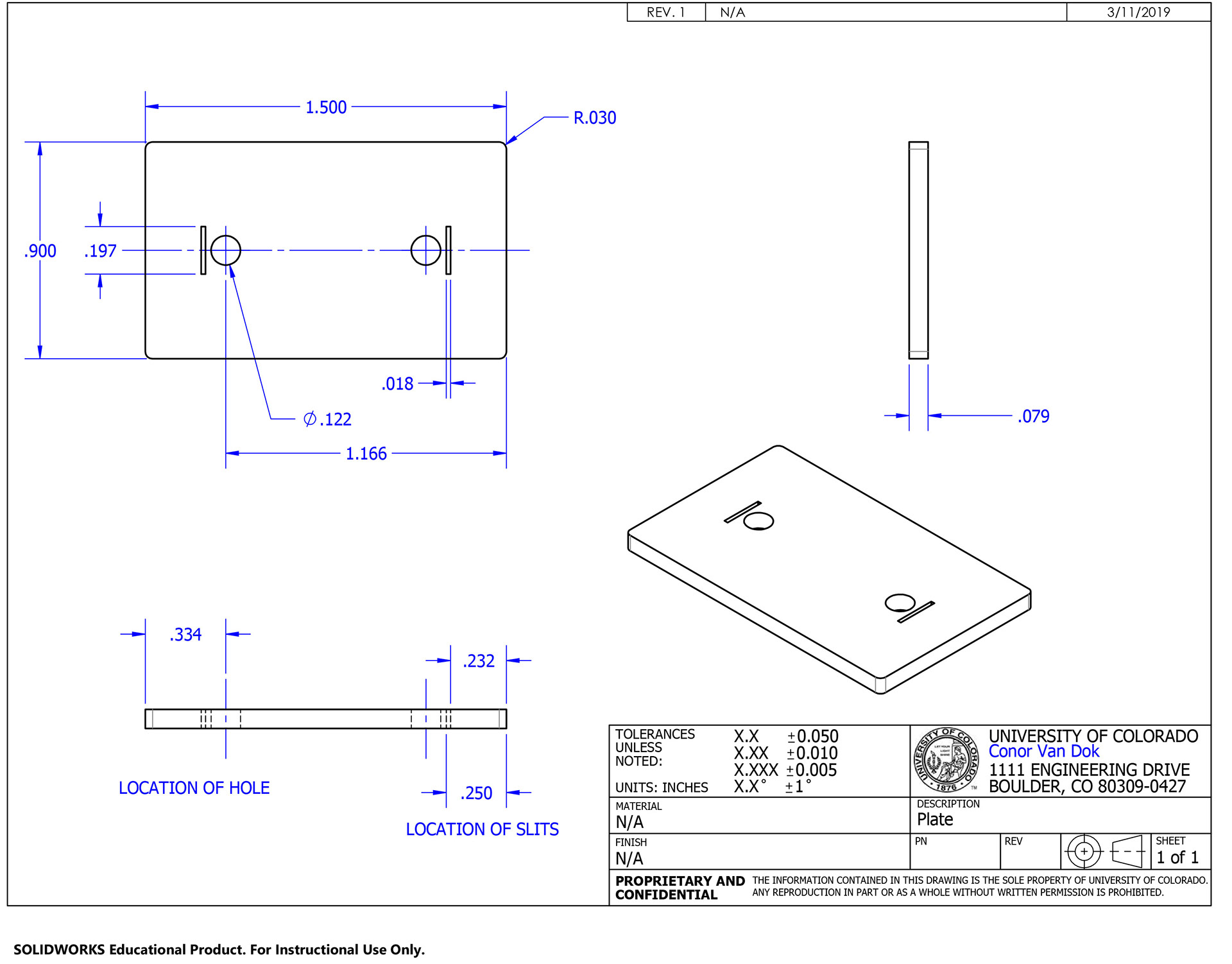

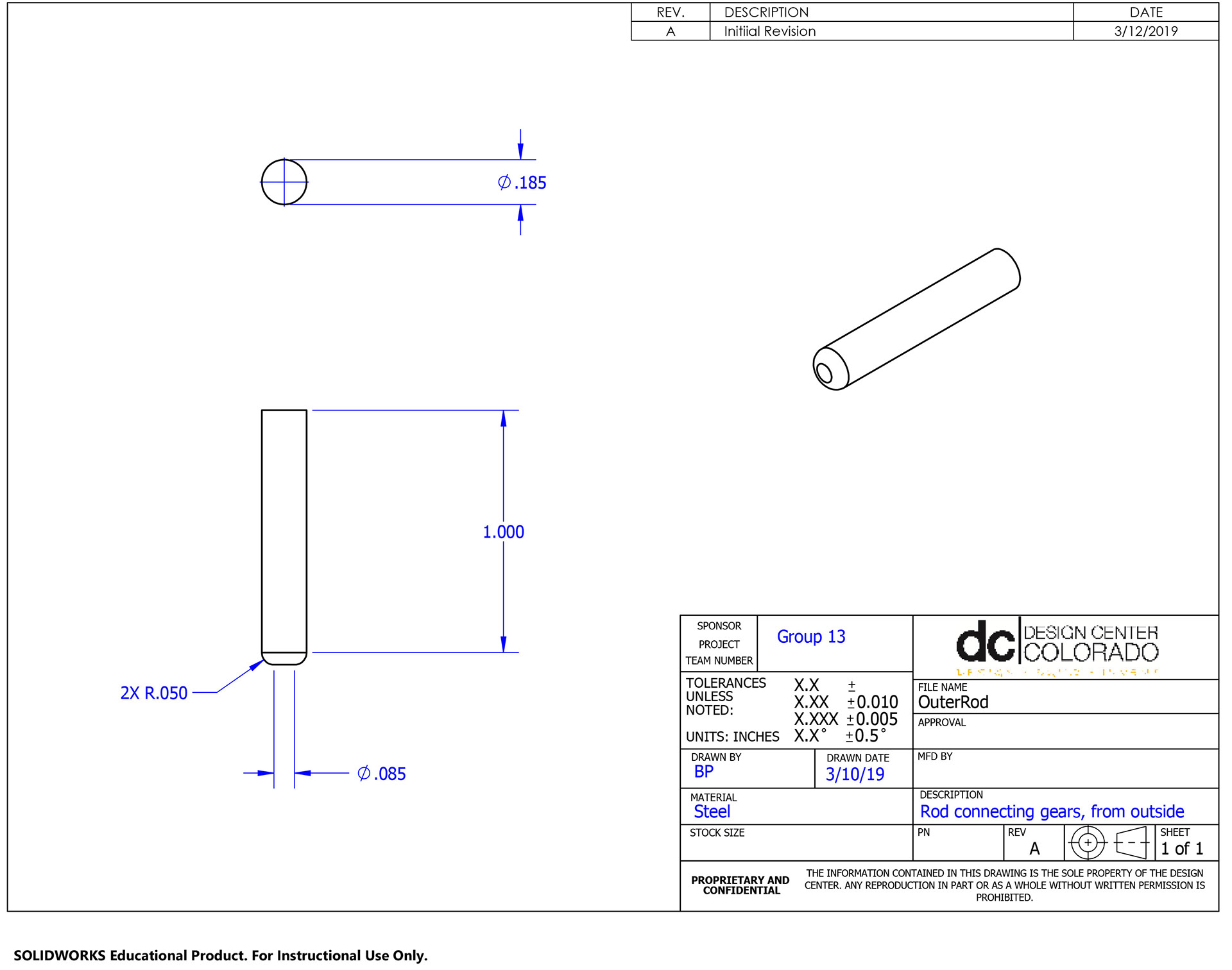

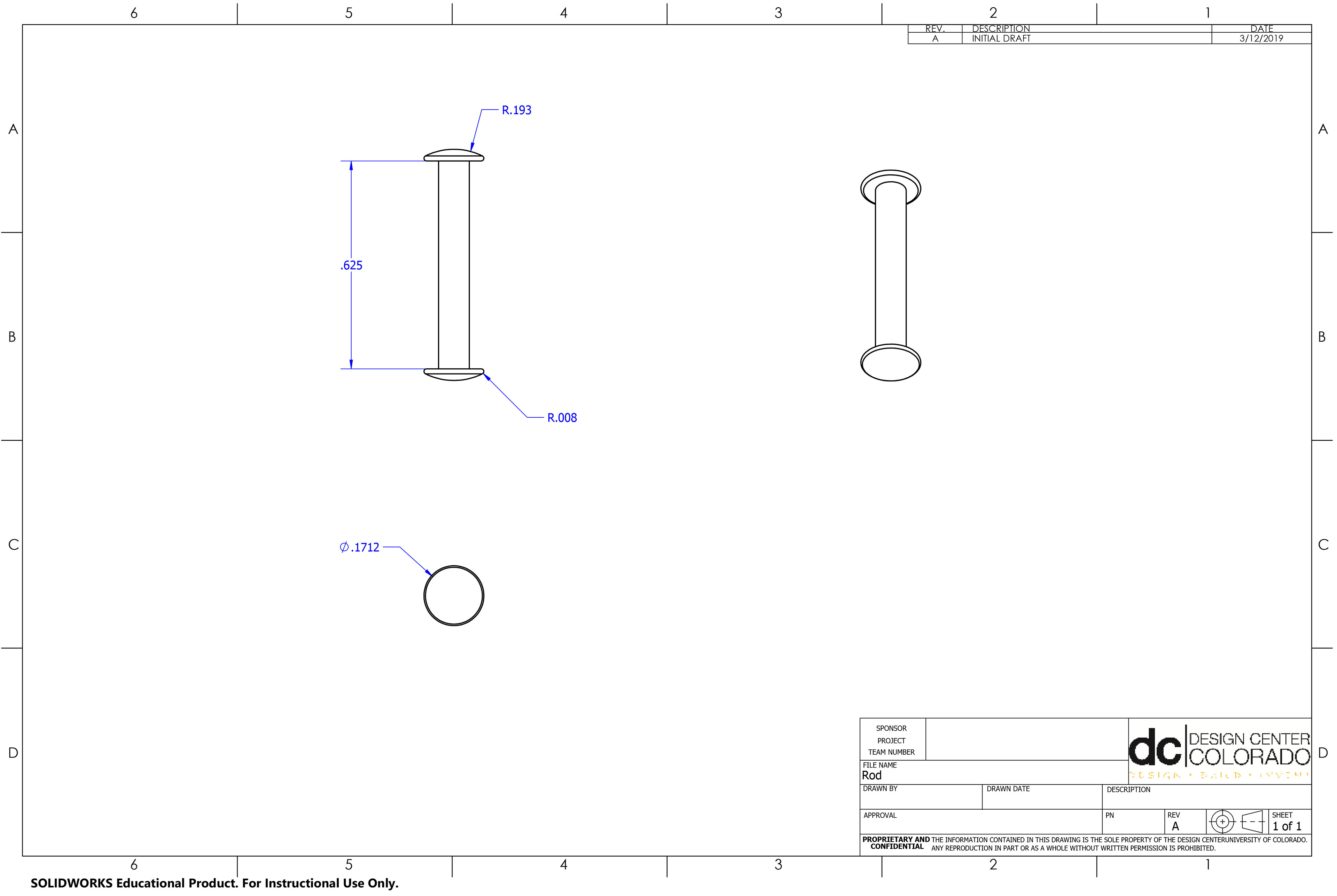

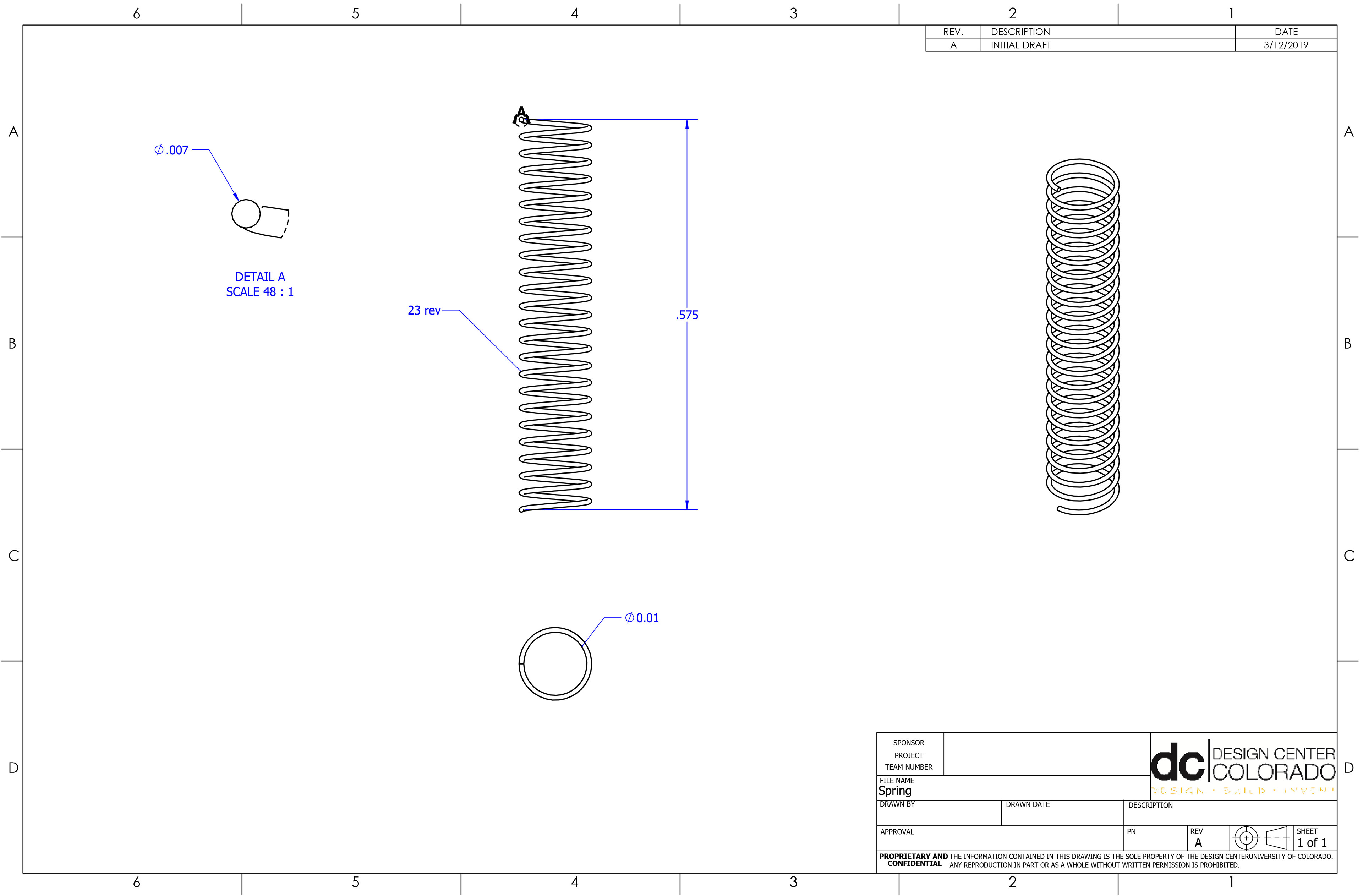

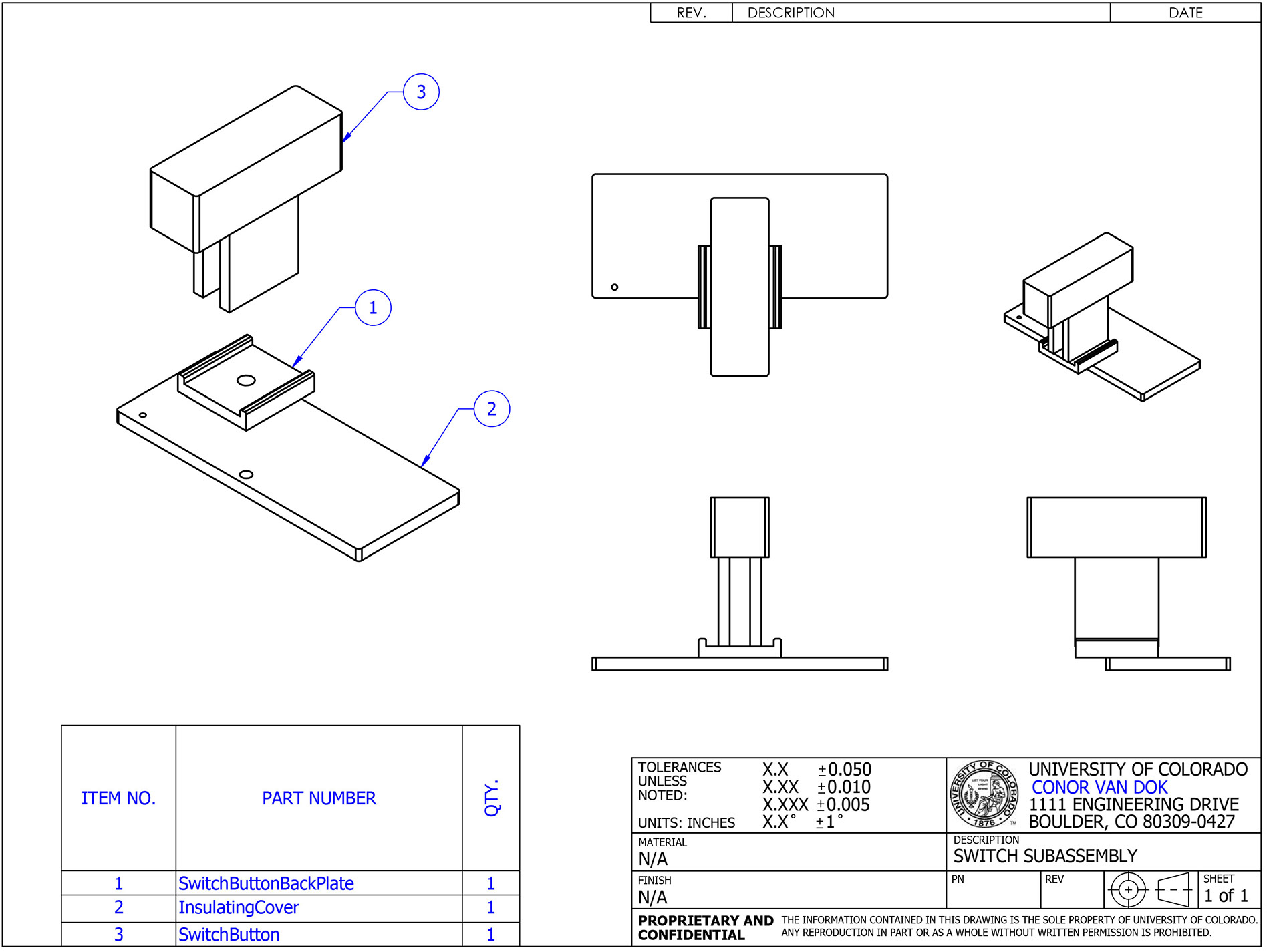

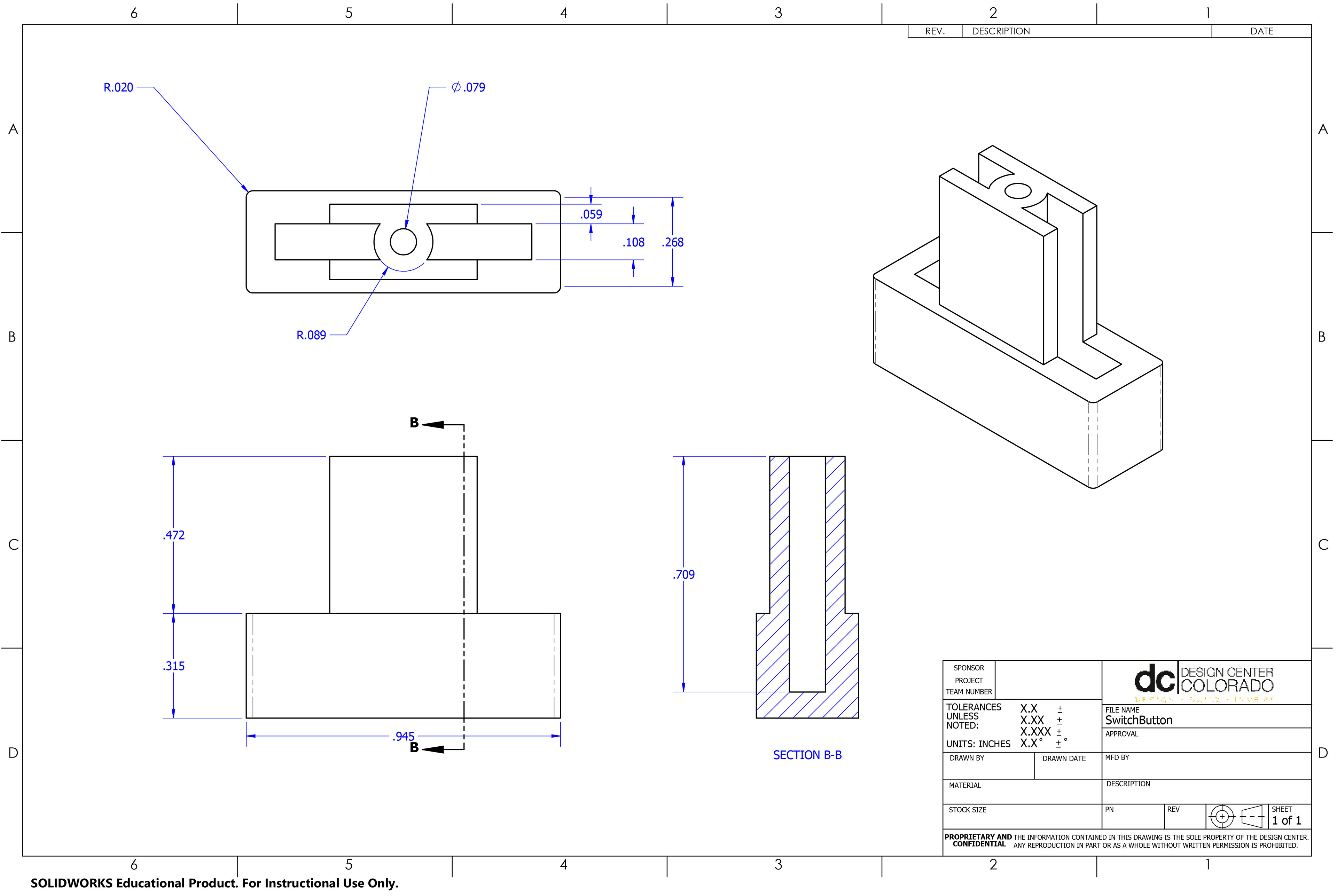

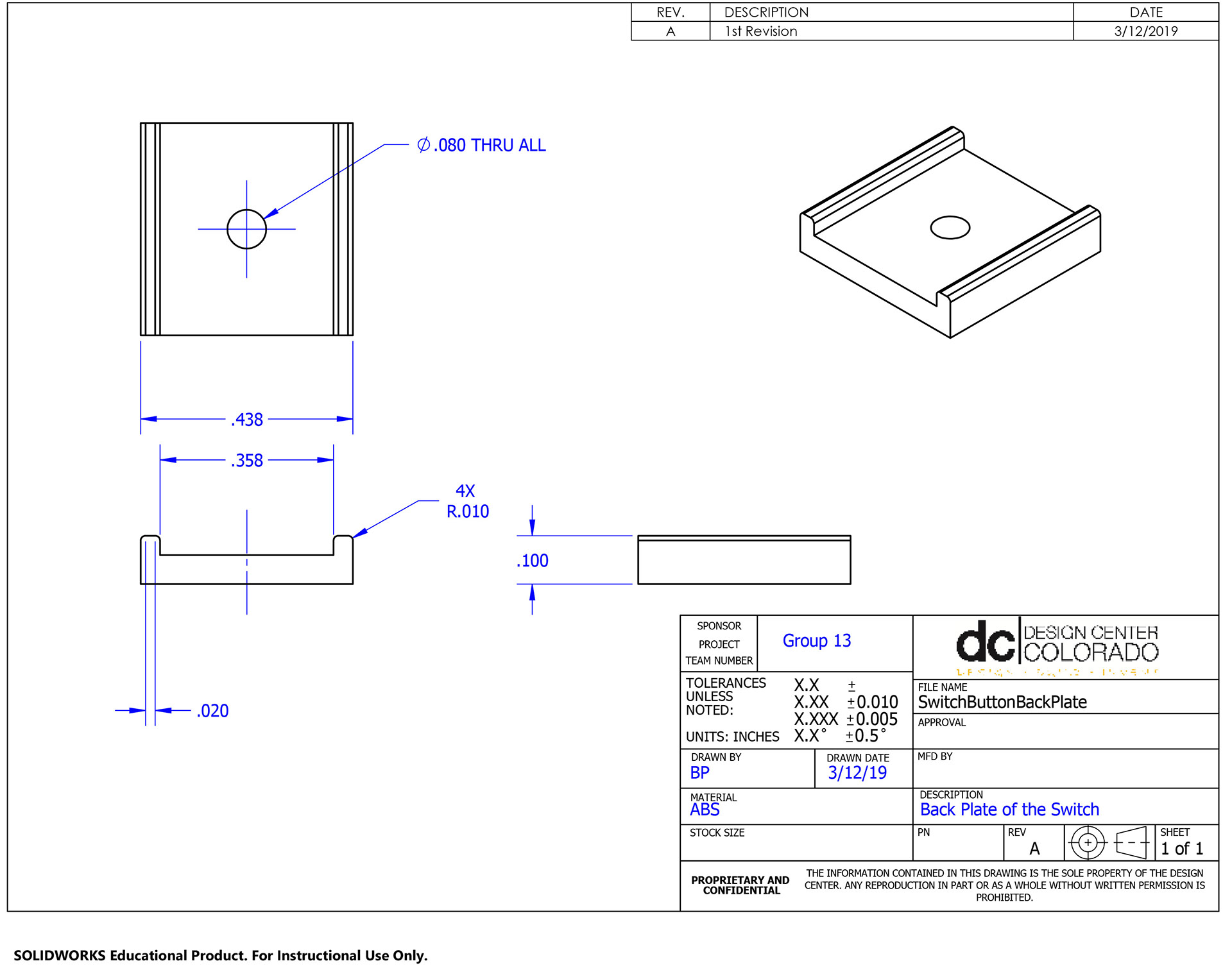

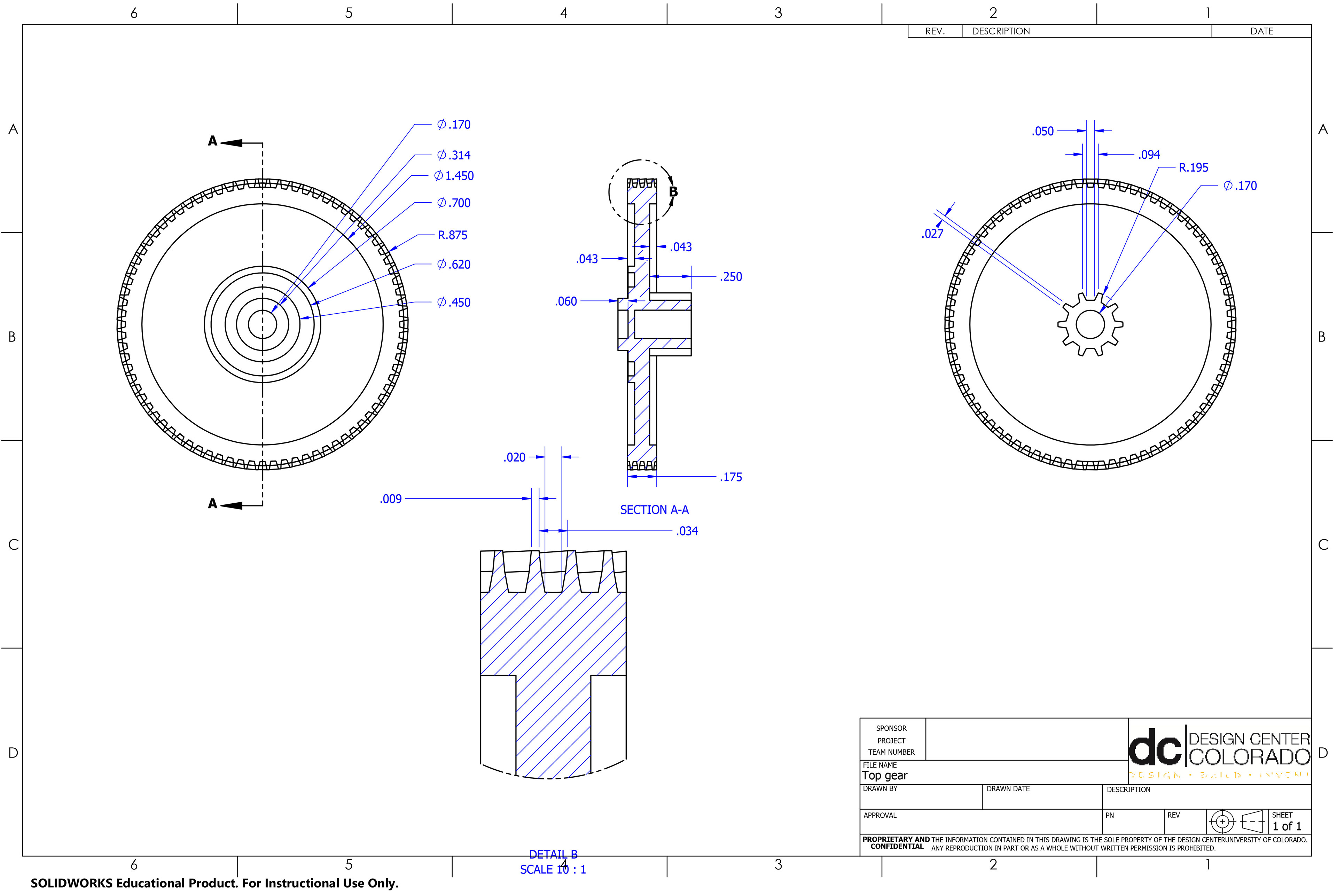

The project was broken into steps throughout the semester. First we disassembled and documented the order and size of the parts as we went. We then split the 20 or so parts between us and modeled them using SolidWorks. Next we created drawings and had to assemble our SolidWorks models; this was a challenge because everyone's measurements seemed to be slightly off. We then created a drawing package, including BOM and revisions. Finally, we created process documents that detailed assembly instructions including the fixturing and tools required for each assembly station.

Solution

The end product was a document that could be used to replicate an automatic can opener given the proper tooling and materials.