Summary

Sector: Bicycles

Software: SolidWorks

Manufacturing: Machining, MIG Welding,

Project Time: 8 weeks

A drill bike, a team, and a racecourse. I worked with a group of students to design, manufacture and race a drill powered vehicle. I was the frame designer, CAD designer and welder for my team of 5.

A major challenge in our design was creating the drive-train. The design included a 1020 low-carbon steel plate secured with U bolts around the frame, the drill secured with another U bolt. To minimize stress on the shaft we used straddle-mounted pillow-block bearings to ensure the components would remain inline.

Design Process

Our team entered the sport class of the competition which meant the bike had to be fast, maneuverable and short enough to fit within the 36” tunnel obstacle.

The design process started with initial sketches of the bike and overarching design constraints it had to fit within. Then we used the weldment tools within SolidWorks to model the bike.

3D Render

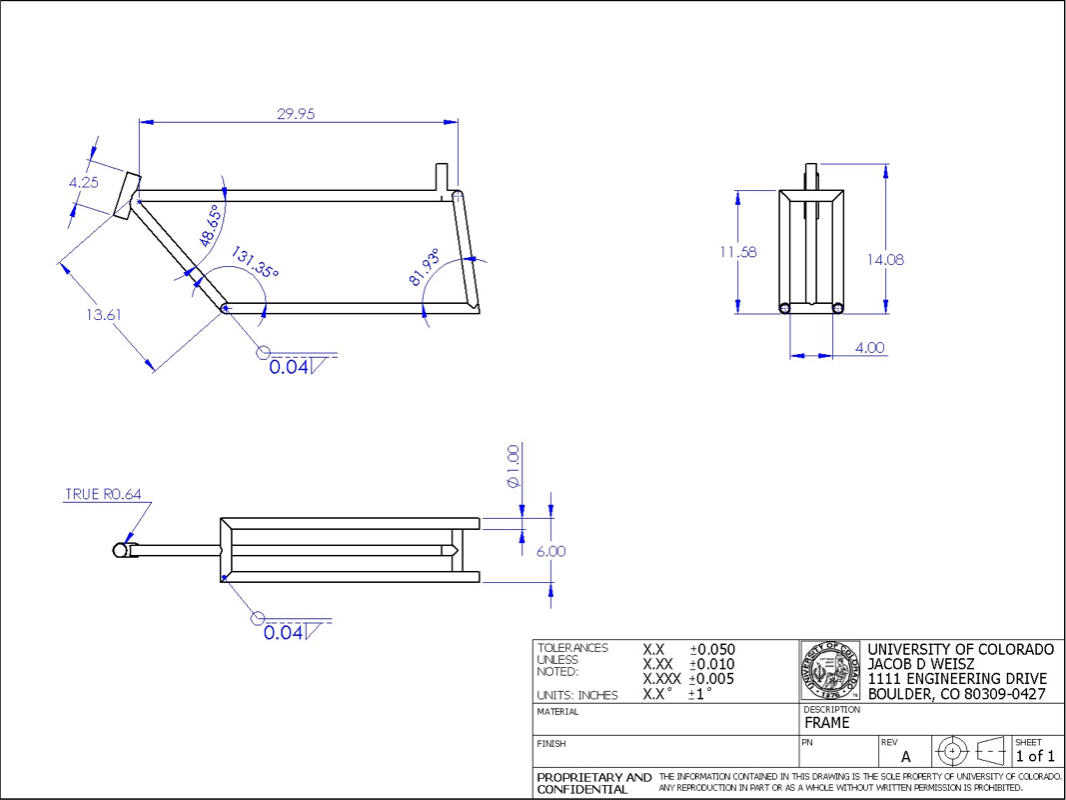

Frame Drawing

Solution

We took 2nd place in the speed class. We found that a low center of gravity helped with the speed and maneuverability and regretted designing such a large turning radius.

The Green Machine