Summary

Sector: Fashion, Entrepreneurship

Software: Matlab, SolidWorks

Manufacturing: 3D Printing, Water Jetting, Laser Cutting

Project Time: 8 weeks

A novel mechanism that converts flat shoes into high heeled shoes by using our novel mechanism with a magnetic snap fastening system. Our team achieved:

• Won 2nd place at College of Engineering Research Symposium (CERS) in the System, Design and Education category.

• Selected for the LaunchBox Idea TestLab, a six-week business accelerator.

• Awarded a provisional patent through Penn State University, U.S. Prov. Pat. App. No. 63/307,796

The major challenges of this project were:

1. Finding and assessing an appropriate mechanism design

2. Balancing strength of the mechanism and force to actuate the mechanismDesign Process

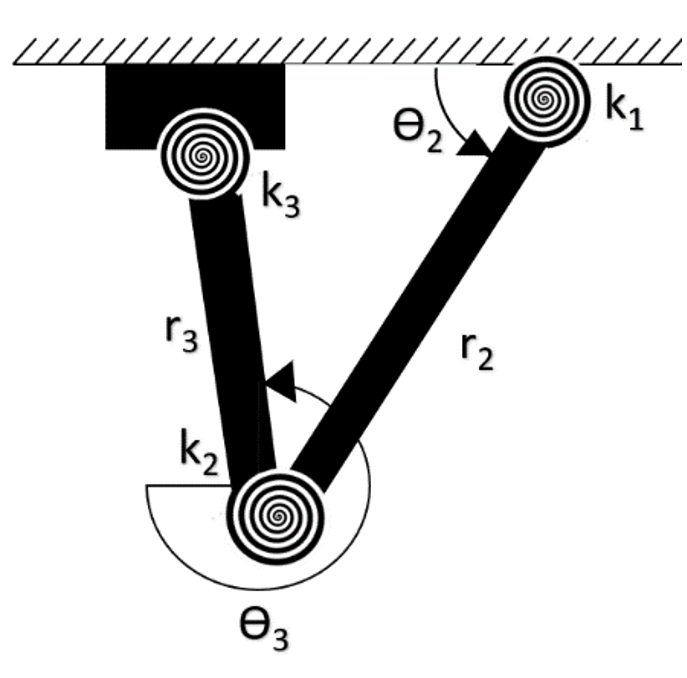

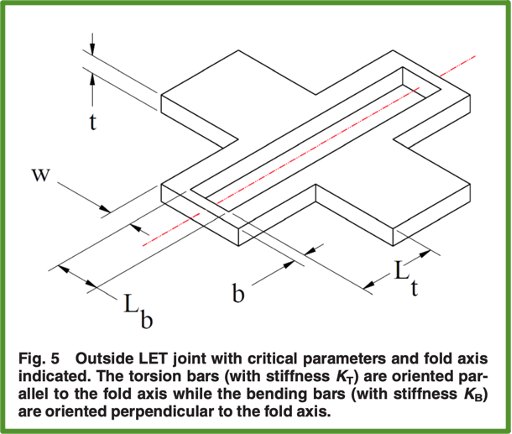

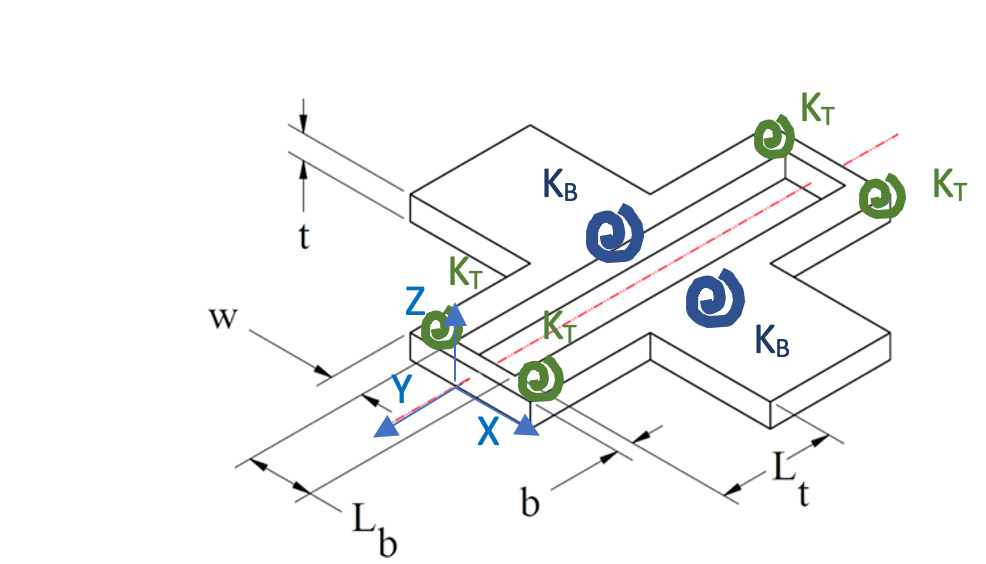

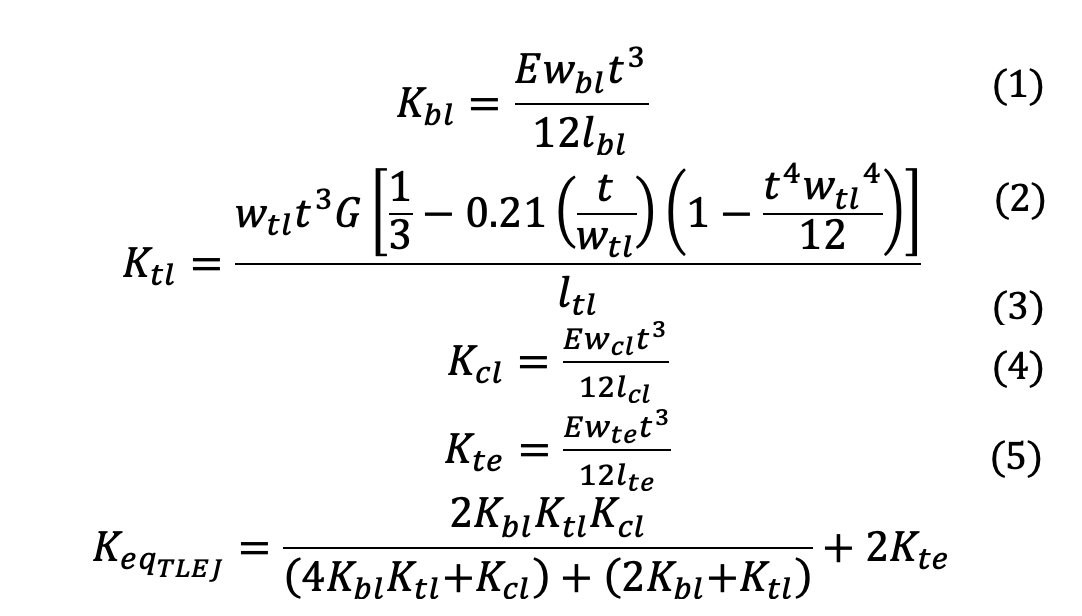

The design was based on a slider-crank mechanism with three flexible joints known as lamina emergent compliant hinges. These joints are modeled as springs in the upper left in the figure on the right in accordance with the Pseudo-Rigid-Body Model (PRBM). The PRBM provides a simple method to analyze conservative systems that undergo large and non-linear deflections. This system has one degree of freedom, which is essential to keeping the mechanism’s motion reliable and user friendly.

Additive manufacturing made it easy to iterate between different LEM joint designs. PLA proved sturdy enough for researchers to test the prototypes with their bodyweight. Magnets created a fastening method which made it easy to switch the mechanism from a flat to high heel state while keeping the mechanism stable in that state. The motion of our deployable heel design was analyzed with simulation via SolidWorks FEA and analytically via MATLAB.