Summary

Sector: Non-Profit

Software: Onshape, Python

Manufacturing: Sheet Metal

Project Time: 6 week design/build (3 month internship)

What an interesting project this was! As an intern for ALLFED, who's mission it is to feed everyone in the case of a global catastrophe, I built a device to kick start energy production in a scenario of global energy grid disruption. The diagram below shows where the device fits into this scenario. The device is a retrofitted bicycle designed to more efficiently chop wood than using traditional hand tools. This project was publish in Hardware: https://www.mdpi.com/2813-6640/2/2/8#

Device requirements:

1. Only battery operated tools are allowed for fabrication.

2. Safe to operate.

3. Greater output of chopped wood than chopping by hand.

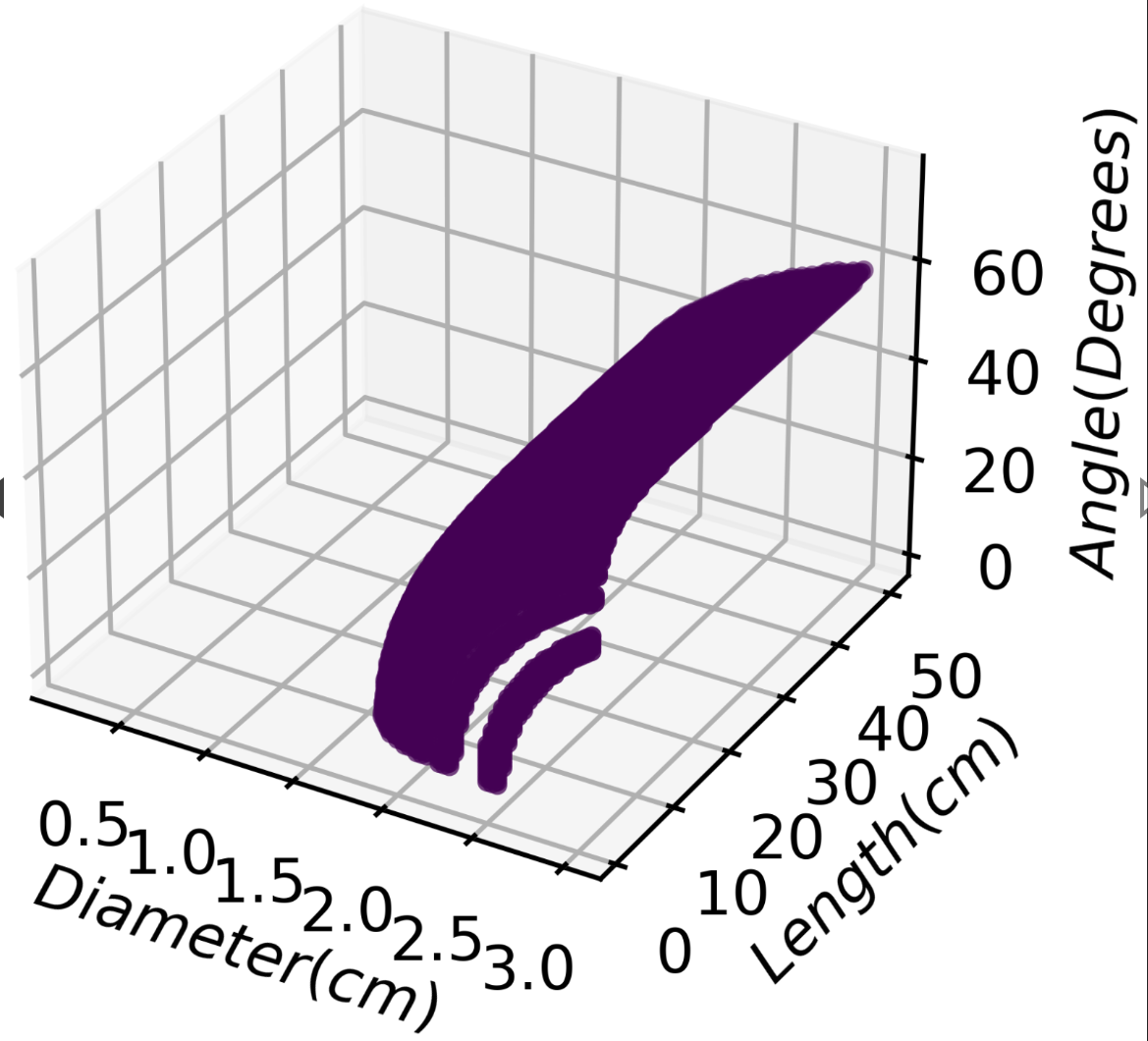

4. Cut wood to a size that can be easily processed by a wood gasifier.

Design Process

First, weeks and weeks of background research to better understand the problem and make sure this makes sense in context. Next, sketches. Design sketching is of form of communication so I take time in crafting sketches that convey design intent.

Solution

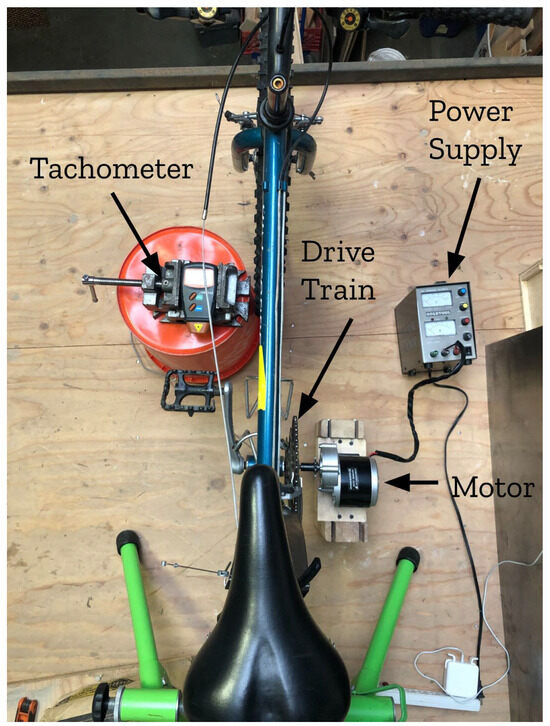

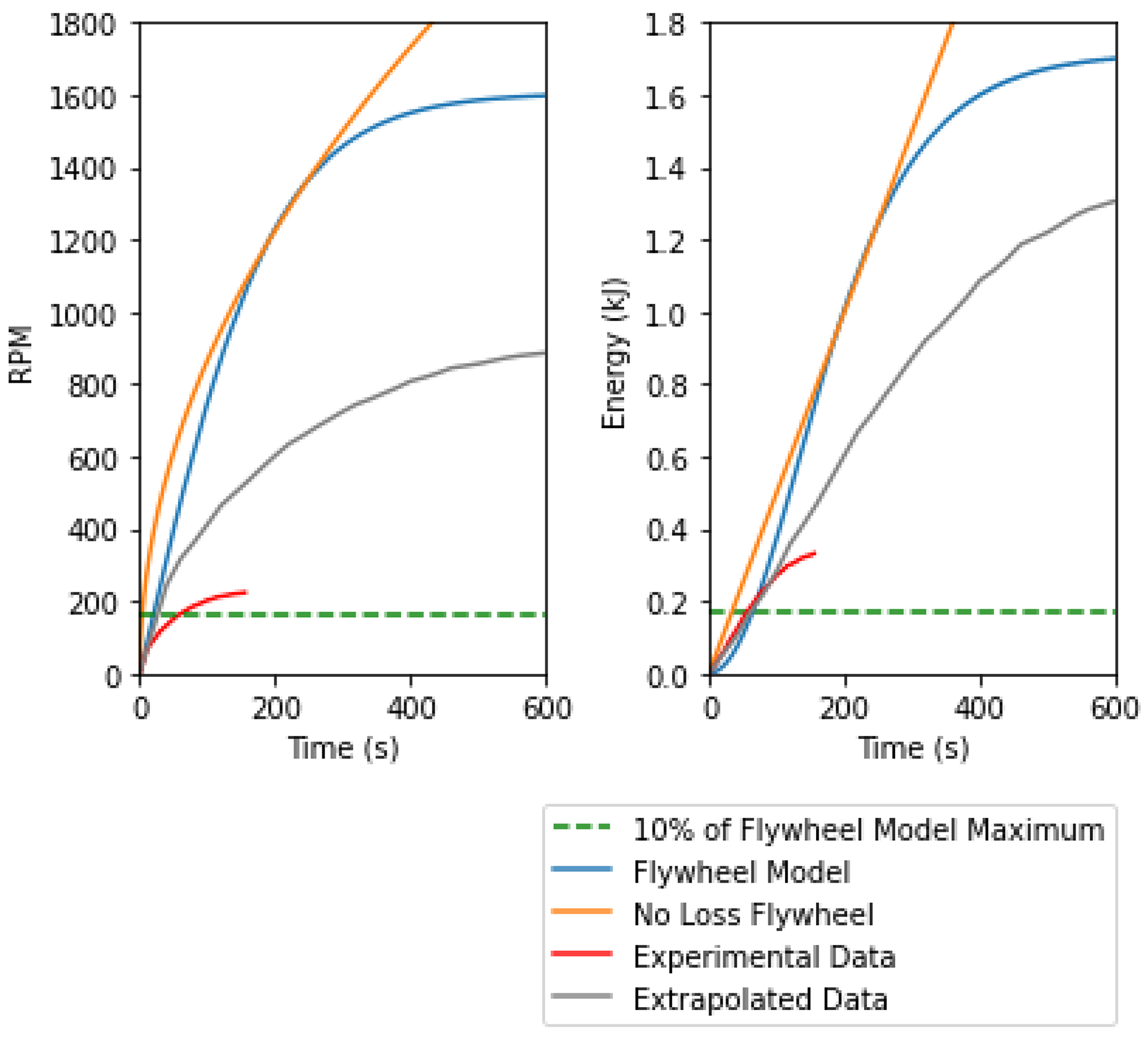

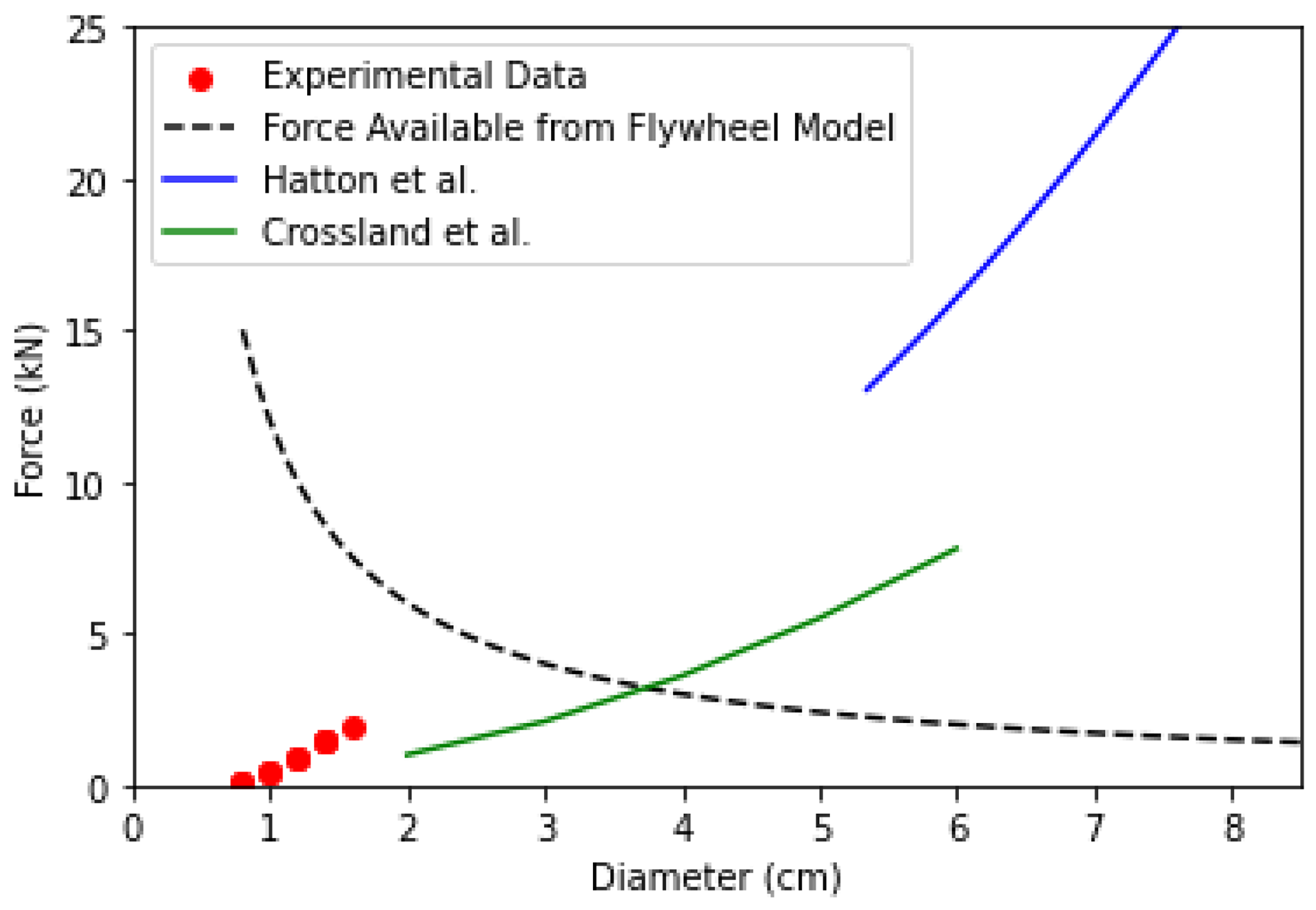

By turning the rear wheel of a bicycle into a flywheel you can store enough energy while pedaling to easily cut sticks. I was able to make a simple setup using a tachometer, motor, and power supply to gather data and quantify the RPM, energy, and force compared to other studies.